What is the Difference Between Pressure and Flow Rate?

28 February 2024, Wednesday

Pressure and flow are two terms that often come across when talking about compressed air systems and air compressors in particular. Understanding the difference between these two terms can increase the efficiency of the bid request processes that you encounter when choosing an air provider. Pressure usually refers to the density of air molecules inside the system in question here and the force they exert on an area. Flow rate, on the other hand, defines how the air volume moves over a certain period, that is, the airflow rate. Although they are similar, the pressure and flow are quite different from each other and cannot be converted into each other. It is important to determine the correct pressure and flow level necessary for the proper use of air. Simply put, the pressure tells how dense the air is, while the flow rate shows how fast this air is moving. Although you are just getting started, understanding these issues will help you when you think about air compressors and compressed air systems. In the following sections, we will explore these basic differences between pressure and flow rate in more detail.

What is Pressure?

Pressure is a measure of the force applied to a surface and refers to the way a certain amount of force is applied to a surface. For example, an amount of force applied to the surface of a compressor over any period causes a certain pressure. A compressor is a tool used to compress air or another type of gas to a certain pressure. To complete this process, the compressor must utilize the correct amount of force. But at the same time, it is necessary to be careful, because if too much force is applied, the pressure on the compressor may become too high. This may damage the compressor or other equipment. That is, we can say that it is important to control the pressure and apply the right amount of force.

What is the Flow Rate?

When we ask the question of what is the flow rate, we are talking about the concept of reduction, which is a volume measure related to the amount of air output of a compressor system. It is also associated with the ability of a compressor to perform and continue performing a lot of work tasks in a certain period. Depending on the length of this ability, the amount of flow may also vary. Usually, the flow rate quantity refers to how much work the compressor can do at the end of a certain period, that is, how much air it will produce to complete the task. Naturally, this is directly related to how quickly and efficiently the compressor can perform the task. While the general answer to the question of what is the flow rate is accepted, the type and capacity of the compressor used can also determine the amount of flow rate. Especially in industrial applications, flow rate measurement can be an important parameter for system efficiency.

How Do Pressure and Flow Function Together?

We often hear the terms pressure and flow rate in various technological and physical processes. So, do we know what they mean? Pressure is the force falling on a unit area of an object and is usually measured in the unit "bar". Flow rate, on the other hand, refers to the amount of passage of a fluid through a certain cross-section at a certain time and is usually expressed in lt/sec units. Since we know, how do pressure and flow rate have a relationship with each other? For example, suppose we need to move a 5kg block along a table. In this case, the flow takes into account how often we need to move the 5 kg block on the table. If the block needs to move only a small distance per hour, a small compressor that can give an air pressure of 7 bar and provide a small amount of air can meet these demands. However, if your application requires you to keep the block in constant motion for hours, you will need a compressor that can provide higher pressure and has a larger capacity to provide proper airflow, for example, it may be a compressor with a pressure of 8 bar. At this point, pressure and flow work together and determine the effectiveness of a system.

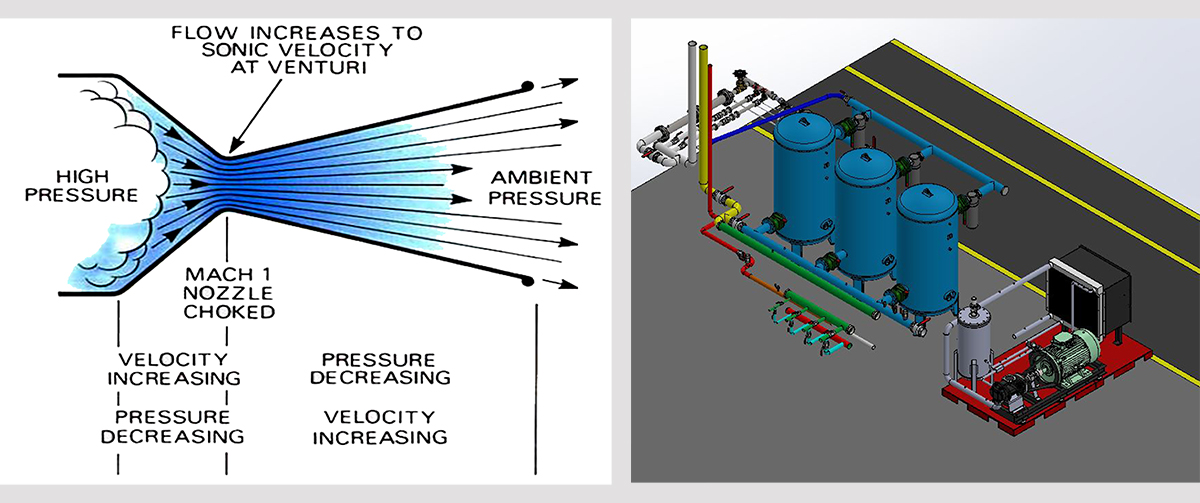

Bernoulli Equation of Flow and Pressure

Regarding hydrodynamics, the Bernoulli principle is used in fluid mechanics and forms the essence of fluid mechanical energy. Since the Bernoulli equation is the result of the principle of conservation of mechanical energy, it can only be used to solve the flow and pressure of incompressible fluids.

Bernoulli's principle: p + 1/2ρv2 + ρgh = C. Where p represents the pressure of the fluid, v represents the velocity of the fluid, ρ represents the density of the fluid, g represents the gravitational acceleration, and h represents the height of the fluid. This equation applies the basic principle of energy conservation to the world of fluids: the total energy of a system does not change.

The Bernoulli equation is used in a wide variety of applications, from the design of aircraft wings to the operation of water turbines. When calculating flow and pressure changes, it is important to take into account the energy passing through the state of an incompressible fluid. This energy is expressed in various forms, such as velocity, height, and pressure.

- p = Pressure in the liquid

- v = The flow rate of the liquid

- ρ = Density of the liquid

- g = Gravitational acceleration

- h = Height of the point / horizontal drop

- C = Constant value

In order for the Bernoulli Principle to work, the following assumptions must be met:

The flow must be in a stable state (the properties of the liquid should not change over time). There must be an incompressible flow in which the density is constant. It needs to be a frictionless flow.

It is necessary that the liquid moves along the flow line and the flow lines do not intersect.

Please Be Careful of High Pressurization

Please be careful with high pressurization, especially when it comes to compressed air systems. "Is there anything wrong?" we should ask, as a matter of fact, the flow rate of the facilities where excessive pressure will be applied may make it difficult to grasp the processes properly. At the same time, understanding the concept of high pressure can be difficult at first. However, it is very important to understand that high system pressures cause serious energy losses and thus high costs. The concept of "overpressure" means that control of compressed air systems is lost and air is supplied above the capacity of the facilities. This can lead to damage to facilities and loss of energy. Therefore, it is of great importance to properly manage and control the air pressure. Especially in large facilities, proper management and controlled implementation of high-pressure air systems are of great importance in terms of energy saving and operational efficiency. So, please be careful when applying "high pressurization", so that you can help prevent serious energy losses.