Advantages of Frequency Inverter Compressors

3 April 2024, Wednesday

Industrial and commercial applications are continually evolving, seeking ways to enhance efficiency combined with modern technology. Consequently, energy conservation and optimizing operational costs are critical. Compressors are among critical equipment commonly used across different industries with a fundamental role in applications like ventilation, cooling, and manufacturing processes. Contrary to conventional compressors, frequency inverter compressors stand out, aligning with modern technological advancements. The frequency inverter dynamically adjusts the functioning speed of the compressor, effectively optimizing energy consumption.

How Do Frequency Inverter Compressors Operate?

Frequency inverter compressors are sophisticated devices with increased energy efficiency and performance. These compressors basically utilize a frequency inverter that regulates the speed of the electric engine, enhancing the efficiency of air or gas compression. The frequency inverter changes the electrical frequency of the engine, dynamically adjusting the engine speed. In this manner, the compressor generates the amount of air based on needs, utilizing only the necessary energy and minimizing waste.

Frequency inverter compressors are equipped with a driver that regulates the frequency to control the speed of the engine. This ensures pressure regulation and can keep the air discharge pressure at the desired level.

Screw compressors ensure more precise operation and increased efficiency when integrated with the frequency inverter system. This feature is particularly critical in industries with changing air demand. The frequency inverter offers a solution to reduce energy consumption and maintain the quality of work. It is a valuable advantage, especially for enterprises that prioritize sustainability and cost-effectiveness.

Advantages of Frequency Inverter Compressors

Torque Control

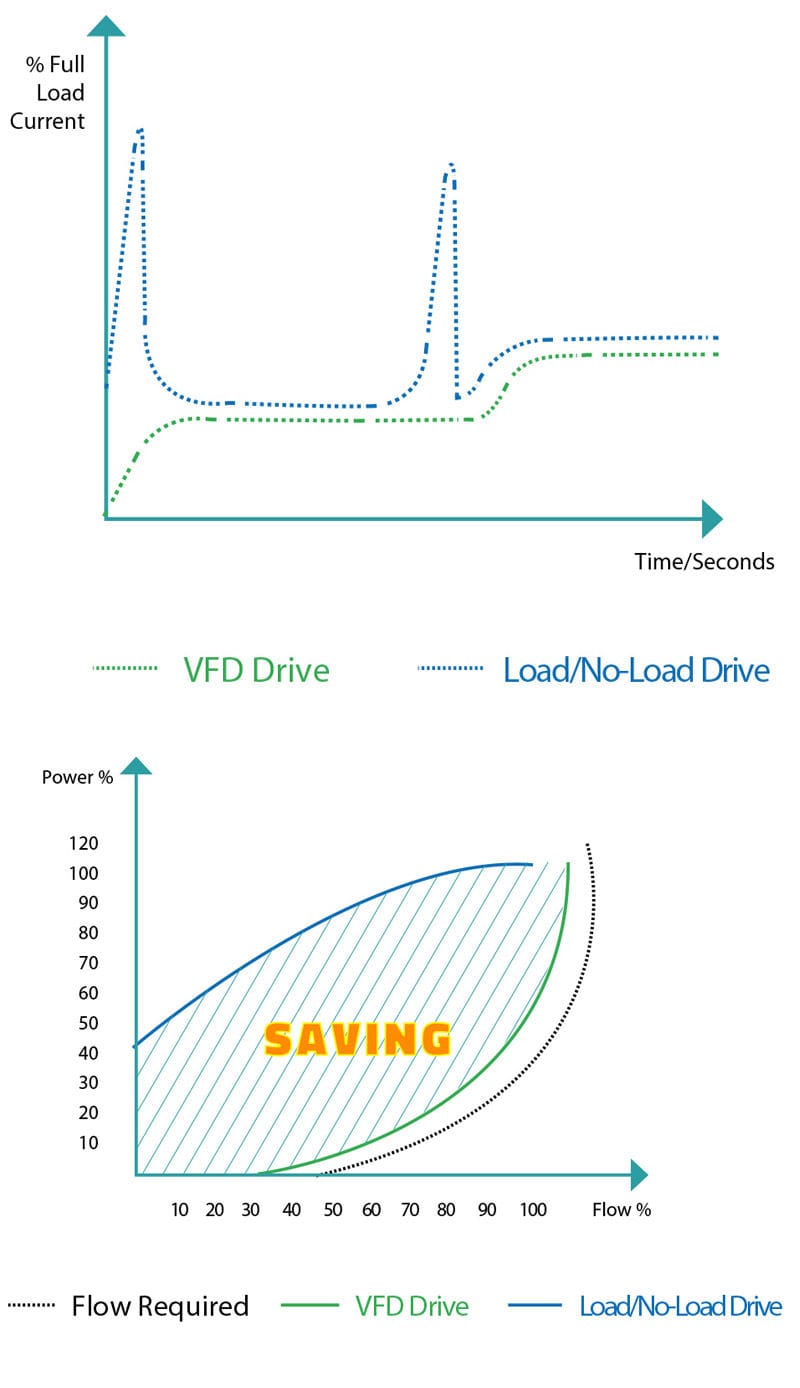

Torque control requires high precision and efficiency, particularly in industrial applications. Advanced control systems are used to ensure the efficient operation of machines that require high power output like compressors. The frequency inverter is one of the key components in these control systems. It adjusts the engine torque by altering the engine speed according to the requirements, thereby optimizing energy consumption This leads to increased energy efficiency in the facilities, resulting in reduced operational costs.

Basic torque control can be achieved in an open-loop system, but the actual system response must be taken into account. In an open-loop system, the frequency inverter monitors the engine current and adjusts the voltage to achieve torque control. However, on the assembly side, if the engine current does not change sufficiently, incorrect results may be obtained.

Speed control

Effective speed control of equipment, including compressors, through frequency inverters, is crucial for industrial-scale businesses. Frequency inverters employ a specific principle to regulate the speed of electric engines. The basic command frequency typically ranges from 0 Hz to 50 Hz but can sometimes reach up to 400 Hz. For example, if the basic frequency of an engine is 50 Hz, setting the command frequency to 400 Hz will result in the engine’s final speed being 8 times its basic frequency.

Compressors and frequency inverters offer industrial facilities the opportunity to reduce energy costs and enhance production efficiency. Speed control enables equipment to operate more efficiently, preventing excessive energy consumption. It enables businesses to adopt more sustainable and environmentally friendly production practices.

Hassle-Free Controllable Start up and Stop

It is possible to optimize the starting and stopping of compressor applications and other machinery by adjusting the engine circuit. It minimizes machinery wear, ensuring an extended lifespan for increased efficiency and longevity. You can facilitate the control and ease of operation by precisely adjusting start and stop times, optimizing the transition from rest to full speed (Start) and from full speed to rest (Stop) for the engine. You can use different start and stop curves by adjusting the correct inverter’s parameters. See the illustrations Fig. 1a to c. This enhances machine efficiency, leading to energy and labor savings.

How Efficiency are the Frequency Inverter Compressors?

Inverter-controlled compressors optimize energy consumption and prevent excessive energy loss. The correct adjustment of the system is crucial for its impact on the compressor pressure. Inverter compressors operate in an eco-friendly manner, contributing to energy savings.

What to Look for When Choosing Inverter Compressors?

Selecting the correct engine power is critical for efficient operation and longer service life of the compressor. Adjusting the pressure capacity based on usage helps ensure correct functioning of the system. As regular maintenance maintains compressor performance, it is important to consider maintenance and serviceability.