What Is Desiccant Air Dryer and How Does It Work?

29 December 2021, Wednesday

The safe operation of machines working with compressed air in production centres such as factory and workshop depends on the correct provision of some conditions. Atmospheric inlet air of the compressor comprises harmful substances and components (oil, dust and moisture). The moisture in the form of steam condenses in the compressed air line. Components that adversely affect the working principles of the machines may cause corrosion, capacity loss and malfunction in devices. Desiccant dryers operate in the removal of the moisture that emerges due to the heating and cooling of the compressed air compressed in the compressors. Desiccant dryers, which are of vital importance for the firms operating in the production field, make the air safe for machines with their functions developed with the state-of-the-art.

Why is Clean and Dry Air Important?

The use of compressed air in production fields and industrial sectors is very common. Compressed air, which is one of the driving energy forms, has to include certain conditions while ensuring the machines running. The air used must be moisture-free, clean and dry in order to avoid problems in machines with high failure cost. There is a certain amount of water vapour within the air obtained from the atmosphere. The water vapour that emerges in different amounts with temperature changes causes sedimentation in the connection equipment of the machines and in the pipes and leads to malfunctions. Dryers are preferred for the removal of moisture and water vapour at compressed air.

What Is Desiccant Dryer?

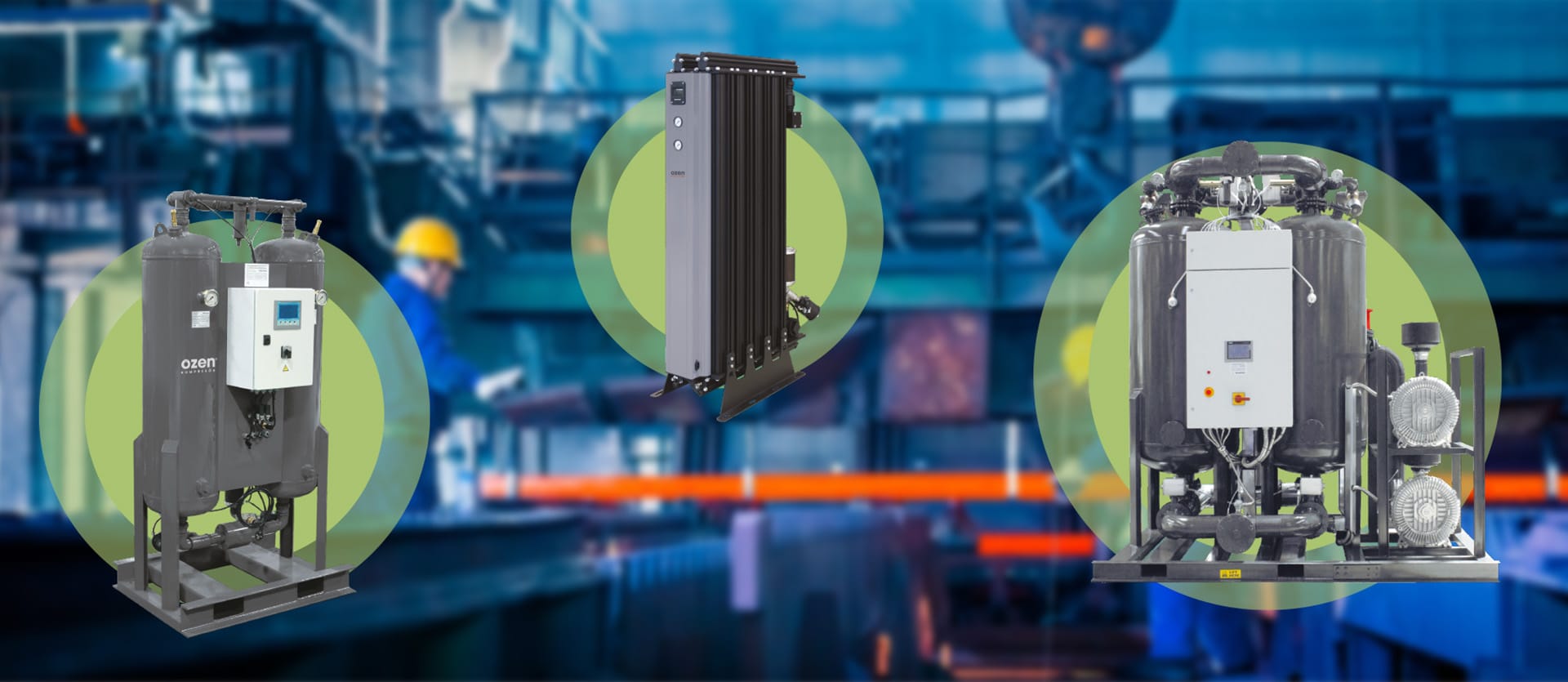

Desiccant dryers, also called chemical, help you obtain efficient results even at high dew points. It provides a radical solution to the problem even at dew points up to -70°C. Devices manufactured with and without heater in different functions are among the indispensable equipment of sectors especially where the production is carried out precisely. Desiccant dryers, which are frequently used in sectors such as pharmaceuticals, food, and electronics, contribute to the uninterrupted continuation of production by preventing the loss of compressed air at a high rate. The devices that fulfil the different needs of production centres are equipped with different technical details depending on the usage area. Depending on the application area, you can prefer the desiccant dryer you need. The devices that provide thrifty production offer high quality compressed air in terms of dew point thanks to their special systems.

The Importance of Using a Desiccant Dryer

Desiccant dryers, also known as air dryers, operate based on the pressure dew point value. The dew point, which determines the content of the air, specifies at which temperature the water vapour condenses into water. Low dew point means low water ratio for compressed air amount. Condensation problem experienced in machinery, pipes and installations designates the high dew point. Equipment that becomes functional with compressed air may encounter with damages that generate loss of production due to high amount of moisture. The solution to solving the problem and preventing it before it happens is to use desiccant dryers.

Desiccant Dryer Manner of Working

The operating system of the desiccant dryers takes place in order to ensure power saving. Air that is moisty and water vapour-involving primarily enters into the heat comparator located in the device. The device, which provides cold air flow, makes the compressed air ready for operation by precooling it.

The vapour in the air turns into a liquid together with the cooling effect. The water, which changes direction and speed, is separated from the air put into operation thanks to the separator. Desiccant dryers have special draining equipment to expel the water.

The water expelled through the equipment in a short time provides that the compressed air is ready for operation. The air, which is purified from liquid materials, passes through the heat exchanger in a dry manner. The air that passed through the heat exchanger in a dehumidified manner also simultaneously carries out the cooling process of the newly incoming moist air. Compressed air that is warm in the desiccant dryer and comes out in a clean manner becomes ready for use and generates the source of safe and efficient production.