How to Calculate the Pressure Required in a Plant?

13 November 2023, Monday

The pressure required in a plant may be calculated based on several factors. Factors such as the nature of the plant, the equipment and processes used, the characteristics of the fluid or gas to be transferred shall be taken into account in the calculation. Steps to be considered in the calculation of the pressure:

Determine the type of pressure required: Pressure is usually expressed as "gauge pressure" or "absolute pressure" for fluids. "Gauge pressure" is measured in relation to atmospheric pressure (the value subtracted from atmospheric pressure), while "absolute pressure" is measured in addition to the atmospheric pressure.

Evaluate the requirements for process and equipment: Pressure requirements may vary depending on the type of plant, equipment and processes used. For example, an industrial plant may have specific pressure requirements for the air compressor, pumping systems, pipelines, tanks or machinery.

Determine the properties of the fluid or gas to be transferred: Properties such as density, viscosity, temperature of the fluid or gas to be transferred shall also be taken into account in the calculation. These characteristics may influence factors such as pressure drop calculations and sizing of pipelines.

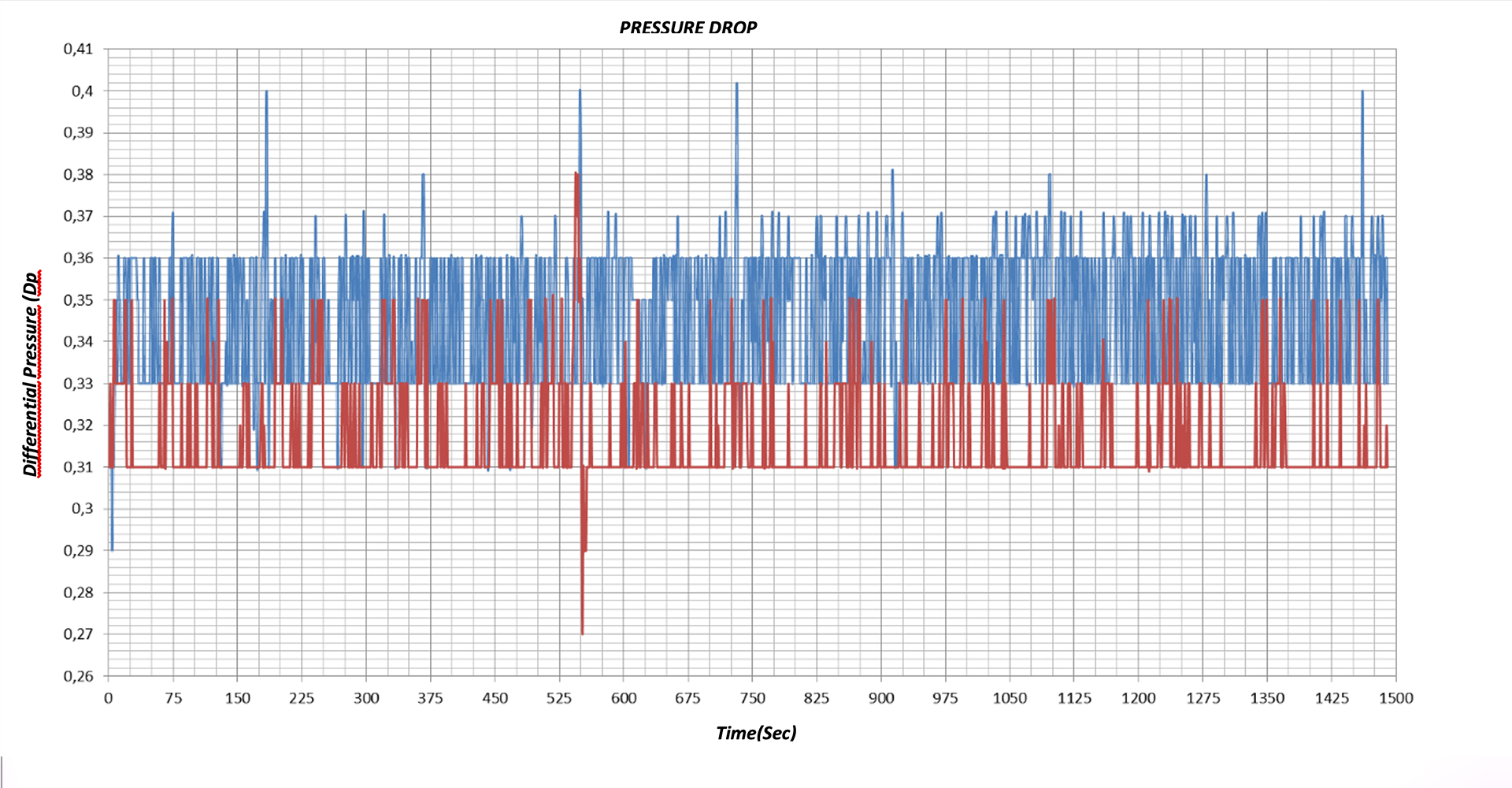

Calculate the pressure losses: Pressure losses occur during the transfer of the fluid or gas in a pipeline or system. These losses may be calculated based on the diameter of the pipeline, flow rate, coefficient of friction and other factors. Pressure losses shall be added to the determined pressure requirement.

Consider the safety factors: It is important to include safety factors in the calculations. For example, you can add additional safety margins to ensure that the operation is stable even in case of unexpected load spikes or system failures.

The steps mentioned above are a general guide for the pressure calculation process. The required pressure may vary depending on the characteristics and requirements of the plant.

What Should Be Considered for the Calculation of Compressed Air?

Some important factors that should be considered while calculating the compressed air requirement for the plant are as follows:

Correct air flow rate calculation: It is very important to correctly calculate the air flow rate required by your operating processes. The air flow rate may vary based on the requirements of the equipment used, the air consumption of the processes and the simultaneous operation condition of the equipment. It is important to rely on real data for the calculation of the air flow rate and to analyse the requirements in clear units of calculation.

Pressure requirements and surges in pressure: It is important to correctly determine the level of pressure required by the processes in your plant. Different equipment or processes may have different pressure requirements. You shall also consider the fluctuations and load increases in the compressed air system. To compensate for these fluctuations, you shall use appropriate equipment such as air tanks or regulators.

Calculation of the pressure losses: In compressed air systems, pressure losses occur between pipelines, filters, regulators and other equipment. These losses depend on factors such as diameter, length, flow rate and coefficient of friction of the pipelines. Correct calculation of the pressure losses is an important factor that affects the system performance and the distribution of compressed air.

Factors of efficiency: The efficiency of a compressed air system is important in terms of energy consumption and operational costs. Factors such as selection of equipment, system design and maintenance affect the efficiency. You shall make an accurate assessment by considering the efficiency factors of the equipment in your calculations.

Factors of safety: Safety is very important in compressed air systems. The pressure level in the system shall correspond to the durability and safety standards of the equipment. It is important to include safety margins in your calculations and consider the safety factors in your system.

These factors are important points to consider when calculating for the compressed air in your plant.

In this article, we have mentioned many details from how to calculate the operating pressure to the points you should consider when calculating the compressed air pressure. By following these details, you can calculate the right compressed air pressure for your plant.