Importance of Operating Temperature in Compressors

12 February 2024, Monday

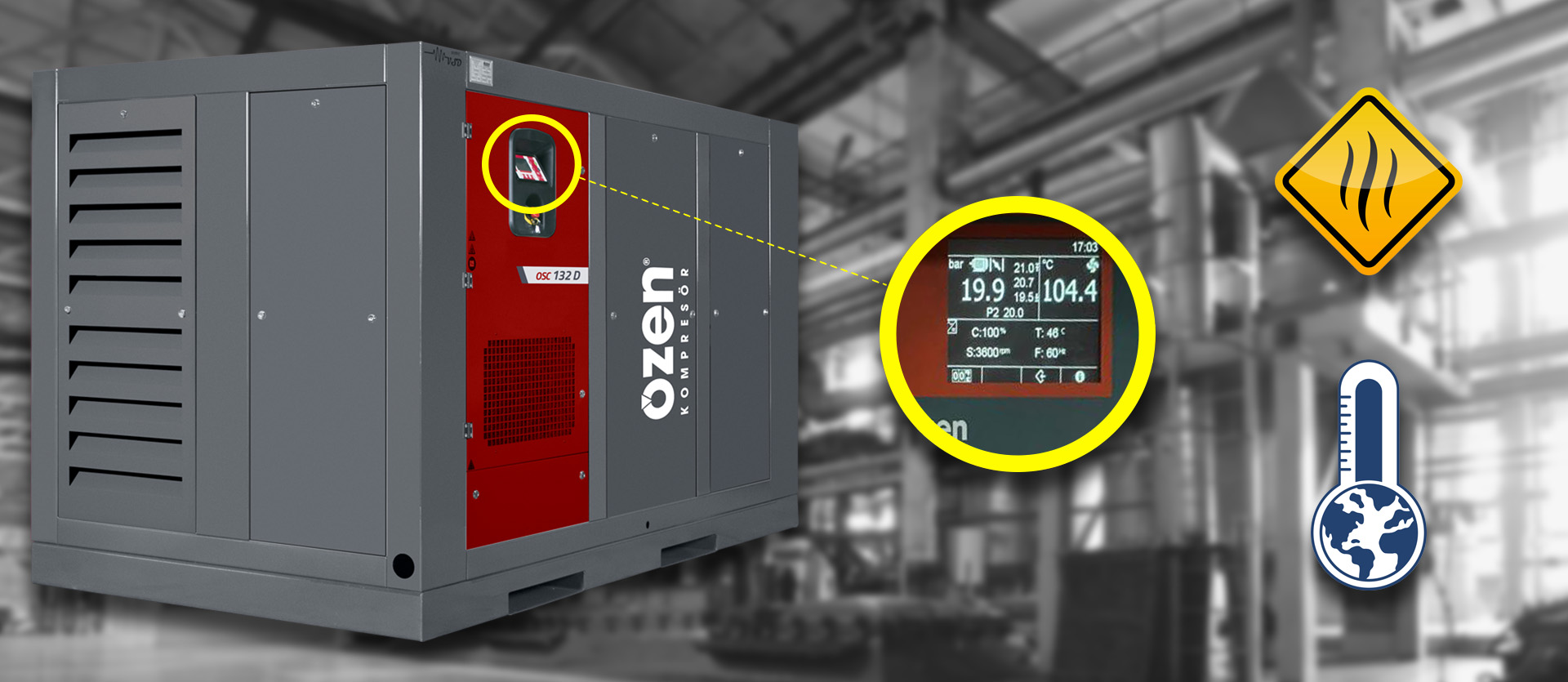

Efficiency of compressors emphasizes the importance of temperature control. According to the first law of thermodynamics, energy cannot be created or destroyed, but can be transformed from one form to another. Motors receive electrical energy from the power source, but due to friction, this energy cannot be fully transformed into mechanical energy. Compressors are important equipment used in industrial and commercial applications. They suck and compress the air, and this typically causes increased operating temperatures. Such increase in temperature can impact the performance of compressors and shorten their service life in the long run.

Motor’s maximum temperature rating can significantly impact the efficiency and service life of a compressor. Air compressors are exposed to intense and continuous operation periods, which means the motors should be resistant to high temperatures. Therefore, the operating temperature of compressors should be specified according to the capacity and operating conditions of the motor. Especially the air compressors used in large industrial plants are exposed to high temperatures, which can directly impact the service life of motors. Controlling the operating temperature of the compressor and ensuring restriction of temperature of the motor with its maximum temperature rating are of utmost importance for the efficiency and service life of the compressor.

Operating Temperature Range of Air Compressors

Air compressors can operate within a specific temperature range. Outside this operating range, your compressor can be too hot or too cold, which might prevent it from operating efficiently. Particularly in the environments where the humidity level is high, the level of temperature can rise above the condensing temperature range of your compressor, which can damage the system. Therefore, it is important to maintain the operating temperature of your air compressor within a certain range. Otherwise, adverse outcomes and severe damages might occur.

How Does Temperature Impact the Compressed Air Systems?

You may be surprised when you learn how temperature fluctuations can impact the performance of your compressor. Since these systems are used in industrial environments, ambient temperature is an important factor for maintaining your air in optimum conditions. Temperature ranges of compressors should be observed, otherwise they might underperform. Particularly extremely high or low temperatures will significantly affect the operation of your compressor. Such conditions can shorten the service life of your compressor or reduce the quality of your air. It is therefore necessary to regularly control, and maintain the ambient temperature within a certain range in the area where the compressed air system is located.

If your compressor is located outdoors, it is obvious that it will be exposed to extreme temperature changes. However, the temperature ranges of indoor type air compressors can vary significantly when they are kept in areas without climate control, or in storage rooms without insulation. While installing a compressor for a system, you should aim to limit the potential temperature fluctuations within the environment. This will help preserve the service life and functionality of your equipment and avoid high costs arising from malfunctions and repair works.

Air Density

Lower air density generally corresponds to colder air, because cold air does not hold moisture as much as hot air. This means that the air tends to be drier. Lower condensation and humidity levels make it easier to infiltrate harmful airborne substances, which help eliminate the moisture in ventilation systems more efficiently.

What is the Optimum Operating Temperature Level for Air Compressors?

Optimum operating temperature of equipment is often a matter of debate among experts. However, most of the experts agree that the optimum operating temperature for air compressors is generally 50 to 85°F (10-29.5 °C). When the maximum operating temperature is kept within this temperature range, performance of the compressor can be maintained and its service life can be extended. If you aim to safely distribute the heat generated by your compressor, you can route the excess hot air to the outer environment via air ducts, which are as short as possible, or direct it to another section of your plant and reuse it. In addition, to prevent the hot air feedback to the system, all air outlets should be as far from the air inlet of the compressor as possible.

Another reason for that optimum operating temperature range [50 to 85°F (10-29.5 °C)] of air compressors is humidity. In air systems, moisture should be avoided. The humidity level of air is low, however extremely low ambient temperatures could also be harmful. After a certain level, cold air drives condensation of water in your compressor. If the ambient temperature is too low, the water freezes, expands and damages your compressor internally. Therefore, the optimum operating temperature of the air compressor for keeping humidity level under control and for preventing freezing of the compressor has been specified as 50 to 85°F. Maintaining this temperature range ensures a long service life and efficient operation. That’s why it is crucial to take this optimum operating temperature range into consideration for best compressor performance.