Water Separators in Compressors

14 December 2023, Thursday

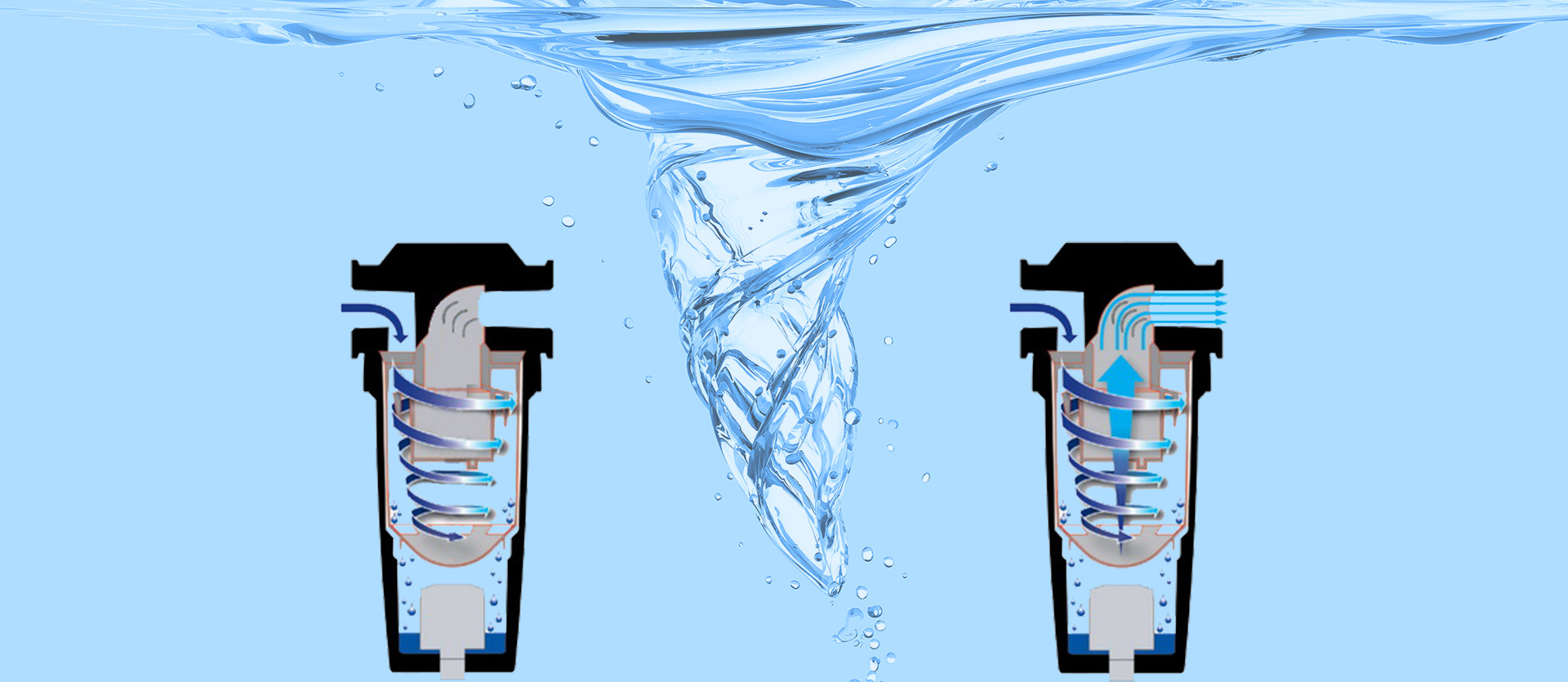

In compressors, the water separator is an important component for cleaning compressed air and discharging water. Water separators, also known as compressor water traps, are part of the filtration system in air compressors.

As compressors operate, moisture in the air can accumulate in the compressor water trap, which can affect the compressor performance. Water separators support the healthy operation of the compressor by ensuring that this moisture is removed without damage. Water separators are usually mounted on a filter to separate the water accumulated inside the compressed air compressor. Water drainage is important for longer and more efficient use of the compressor. Water separators in compressors use their water trapping properties to absorb and effectively filter water accumulated in the compressed air. This increases compressor water trap operating performance and lifetime.

Water Separator

A water separator is an equipment used in compressed air compressor systems. This equipment typically includes a compressor water trap, compressed air water separator and filters. The compressed air water separator improves system efficiency by removing water particles and moisture from the system.

It also prevents lubricant from mixing into the system. Water separators are designed to save energy and prevent unnecessary energy consumption. With its automatic drain function, it automatically drains the accumulated water at regular intervals. As a result, the water separator provides both ease of use and long system life. Water separators are an important component in increasing the efficiency of compressed air systems.

Air Filter - Water Separator

The air filter is an important component used in compressed air compressor systems. The water vapour generated during the operation of the compressor is separated by the compressor water trap and the water droplets and particles are removed from the system by means of this filter. The role of the air filter is to improve air quality and to ensure the protection of the devices in the system. By reducing particle and moisture content, it minimizes wear, corrosion and air loss in the system. The air filter ensures efficient and reliable operation in air compressor systems, providing an effective solution in industrial applications.

What a Compressor Separator Filter Is Good For?

The compressor separator filter plays an important role in compressed air systems. Compressors produce compressed air by compressing air molecules. However, in this process, contaminants can be formed along with water as a by-product of compressors. These contaminants can cause serious problems in pneumatic systems. The compressor separator filter filters out these contaminants, making the air flow cleaner and healthier. At the same time, filtered compressed air extends the life and increases the efficiency of air source equipment. Briefly, the compressor separator filter provides a safer and more efficient working environment by minimizing the negative effects of compressor water traps and contaminants.

What is lubricant - water separator?

A lubricant - water separator is a device used to clean the greasy air generated during the operation of the compressor and to separate lubricant from water. These separators use filters to filter the air and separate the water. Compressed air is a source of energy produced by compressor water traps and used in many industrial applications. However, the lubricant and water particles present in this air can reduce functionality and efficiency. Compressor water traps and water separators separate water from compressed air and ensure cleaner and more efficient operation of compressors. These devices are widely used in industrial plants and workshops.

Why should lubricant and water be separated?

Lubricant and water must be separated because each has a different and specialized function. Lubricant plays a critical role in the operation of the compressor and is used as a lubricant inside the engine. This lubricant reduces friction between compressor parts and prevents them from deteriorating. On the other hand, the compressor's water trap is formed as a result of moisture that may be present in the air and can mix with the lubricant. Water can reduce the performance of the compressed air in the system and cause corrosion of parts. Therefore, the separation of lubricant and water is carried out by a water trap used in the compressor. The water trap captures the water particles as compressed air passes through it, providing clean, dry air.

Designed for Your Compressed Air System

A compressed air system consists of a compressor and compressed air supplementary products designed to meet the needs of your business. The system, which can be built using both screw and reciprocating compressors, is equipped with filters to ensure maximum air performance. Filters trap particles and ensure a high and of good quality air supply. The long-lasting and highly reliable compressed air system plays an important role in increasing the efficiency and performance of your business.