How Should the Compressor Room Be Like?

14 July 2021, Wednesday

Good planning for the compressor room is important for the efficient operation of the compressed air system. Not paying enough attention to the layout of the compressor room in businesses results in temperature fluctuations, equipment failures and decrease in efficiency.

Although an ideal installation cannot always be performed due to budget as well as space or time restrictions where the system will be placed, we have compiled for you the points to take account of installing a compressor in a new plant or making improvements to the existing system.

Points to be Considered While Designing the Compressor Room

While the compressor room is being prepared, care should be taken to ensure that it has a location that will not be affected by dust and dirt, is good for clean and cold air inlet, and has low temperature differences (between 2-46 °C).

It is a condition to build the compressor room on a safe ground. The room needs to have a certain size and height (it is recommended to have a height of 1.5 meters relative to the compressor).

Regular and appropriate maintenance of the compressor is exceedingly important in terms of the operation of the system effectively. Unless the required maintenance is performed, the compressor efficiency will decrease. Therefore, care should be taken to ensure that there is enough space around the compressor for maintenance.

Furthermore, it will provide an advantage if the compressor room has acoustic insulation and thermal insulation. It is recommended that the ventilating fans of the compressor room be on the air bleeding side of the compressor. Thus, it is ensured that the compressor accesses clean air more easily and quickly.

1-Compressor System Layout: Select a dedicated and central compressor room close to the point-of-use.

The compressor room should be placed as close as possible to the point-of-use. Minimizing the distance that the compressed air must travel to access all usage areas helps minimize the amount of compressed air pipes, pressure decrease and possible leak points. And, this increases your energy efficiency.

Enough clearance should be left around the machines for appropriate ventilation of the compressor room. Be sure to consult your compressed air manufacturer for the clearance measurements required for cooling and equipment maintenance. While making a settlement, new investments that may be had in the future for the purpose of capacity increase or backup should definitely be taken into account. Enough space should be left for service and operating around compressors and auxiliary equipment.

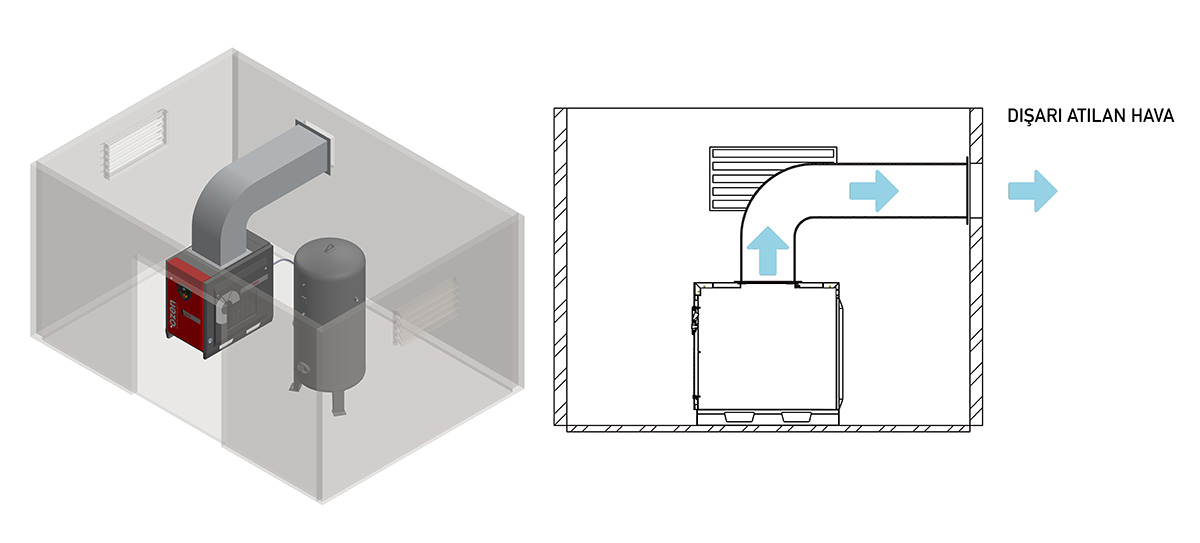

If the difference between the outlet pressure of the suction fan located in the compressor and the outlet pressure of the ventilation duct system is less than 70 Pa, Figure 1: Type A should be preferred.

Figure 2: TYPE A

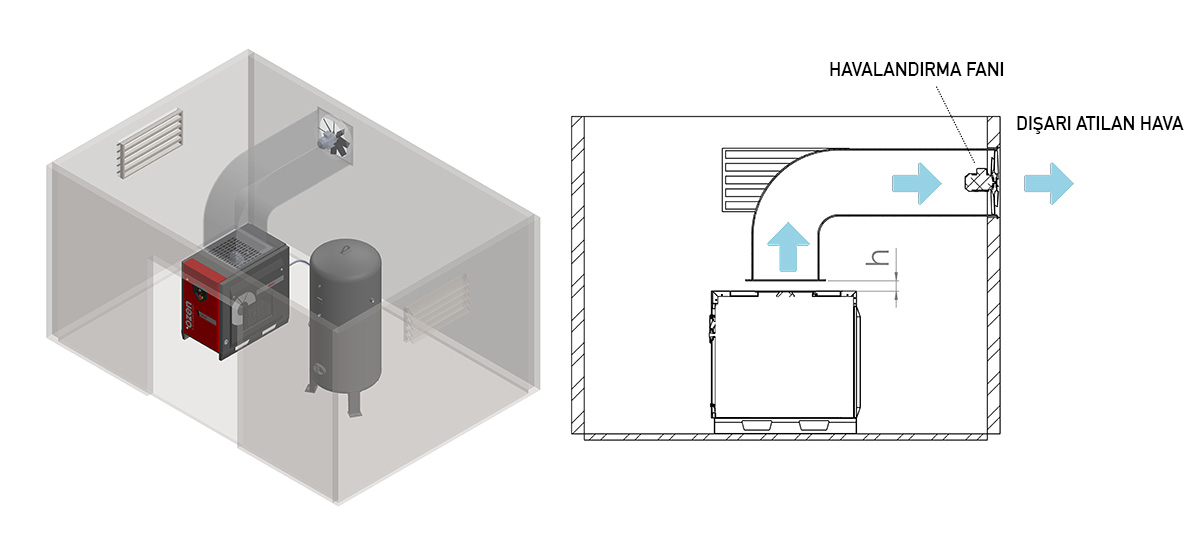

If the difference between the suction fan located in the compressor and the ventilation duct is greater than 70 Pa, Figure 3: Type B should be preferred. When Figure B is preferred, the clearance (h) between the compressor and the ventilation hood should be between 200-300mm.

Figure 4: B TYPE

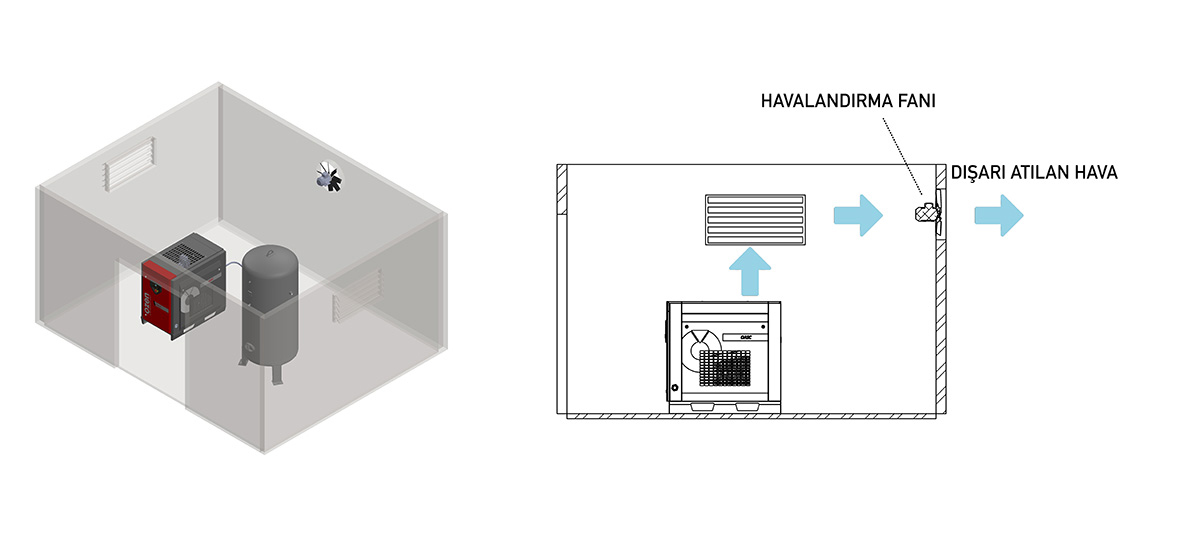

In case of using a fan to evacuate the hot air expelled from the air compressor out of the compressor room (Figure 5:Type C), the capacity of the fan needs to be as close as possible to the cooling fan capacity of the compressor. In case of making a mistake in the dimensioning of the fan that expels the hot air, there will be a vacuum in the room or the hot air cannot be adequately expelled. In this case, the compressor will overheat.

Figure 6: TYPE C

2- Provide a Fresh Air Inlet

Compressor inlet air must be clean for trouble-free and efficient operation. Make sure the compressor room is free from heavy contaminants such as dust or corrosive chemical vapours. Dust and dirt particles cause wear. During the installations where the surrounding air has a high dust concentration, a pre-filter such as a cyclone, panel or rotating band filter should be used. In such cases, the pressure decrease caused by the pre-filter should be taken into account during the design phase of an installation.

3- Provide Appropriate Conditions for Room Ventilation

Because the compressors generate heat, ventilation of the compressor room adequately is vital. If possible, the air inlet should be placed against a northward wall to provide shade during the warmer summer months. The grille and air stream damper units prevent foreign materials from entering and eliminate cold air stream. While the inlet should be positioned as low as possible on a wall, the thermostatically controlled ventilating fans should be placed at the highest point of the opposite wall. Always consult an expert when selecting ventilation methods. Remember that many good installations fail due to the improper cooling methods.

4- Provide the Condensate Management

The provision for drainage for the processing of the condensate incoming from the compressors, aftercoolers, dryers and air receivers is equally important. Concentrated contaminants caused by the oil-injected equipment should never be discharged into the sewers without separating them from the water or filtering. Remember to follow local regulations regarding the disposal of condensate from the compressors as in the coolers, dryers and air receivers.

5- Ensure Compliance with Health and Safety Regulations

The health and safety of your employees should always be the number one priority. Be sure to take the necessary precautions to ensure optimum performance and reliability of the compressor equipment, which is a vital part of the production process.

If the compressor has been placed in an area of a building that is used for other purposes or near personnel doing other tasks, service accessibility as well as health and safety conditions also need to be taken in consideration.

Remember to consider other processes in your plants and whether they will interfere with, break down, or potentially damage your compressor system thereof.