What is Gearbox System on Screw Compressors?

17 May 2024, Friday

Screw compressors stand as crucial equipment extensively used in industrial applications, playing a critical role in fulfilling air requirements. Gearbox systems constitute fundamental components in these compressors. The gearbox system is a mechanism used to control the revs and speed of the screw matching parts of the compressor, playing a crucial role in optimizing the air efficiency in the compressor. This system optimizes the screw speed, allowing the compressor to generate more air volume and achieve maximum efficiency while maintaining energy consumption at lower levels. The gearbox system also enables automatic maintenance features, including pressure and temperature monitoring. This capability allows to manage compressor speed freely and much more efficiently.

Gearbox systems play a very critical role in enhancing the efficiency of screw compressors, ensuring consistent mass production speed, and saving energy costs. To achieve optimal air efficiency, these systems minimize losses in compressor efficiency, ensuring energy-efficient operations.

Essential Principles of Screw Compressors

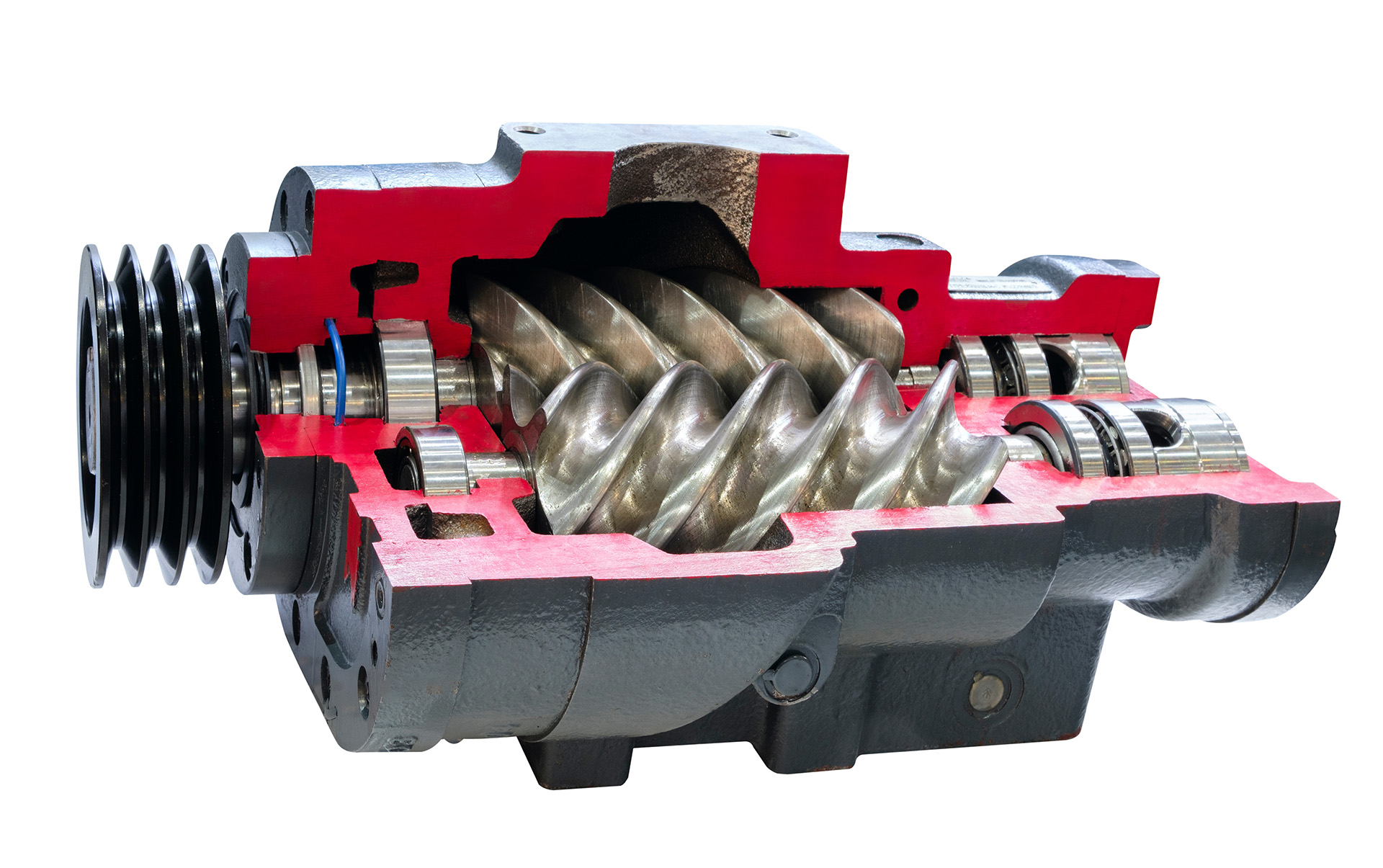

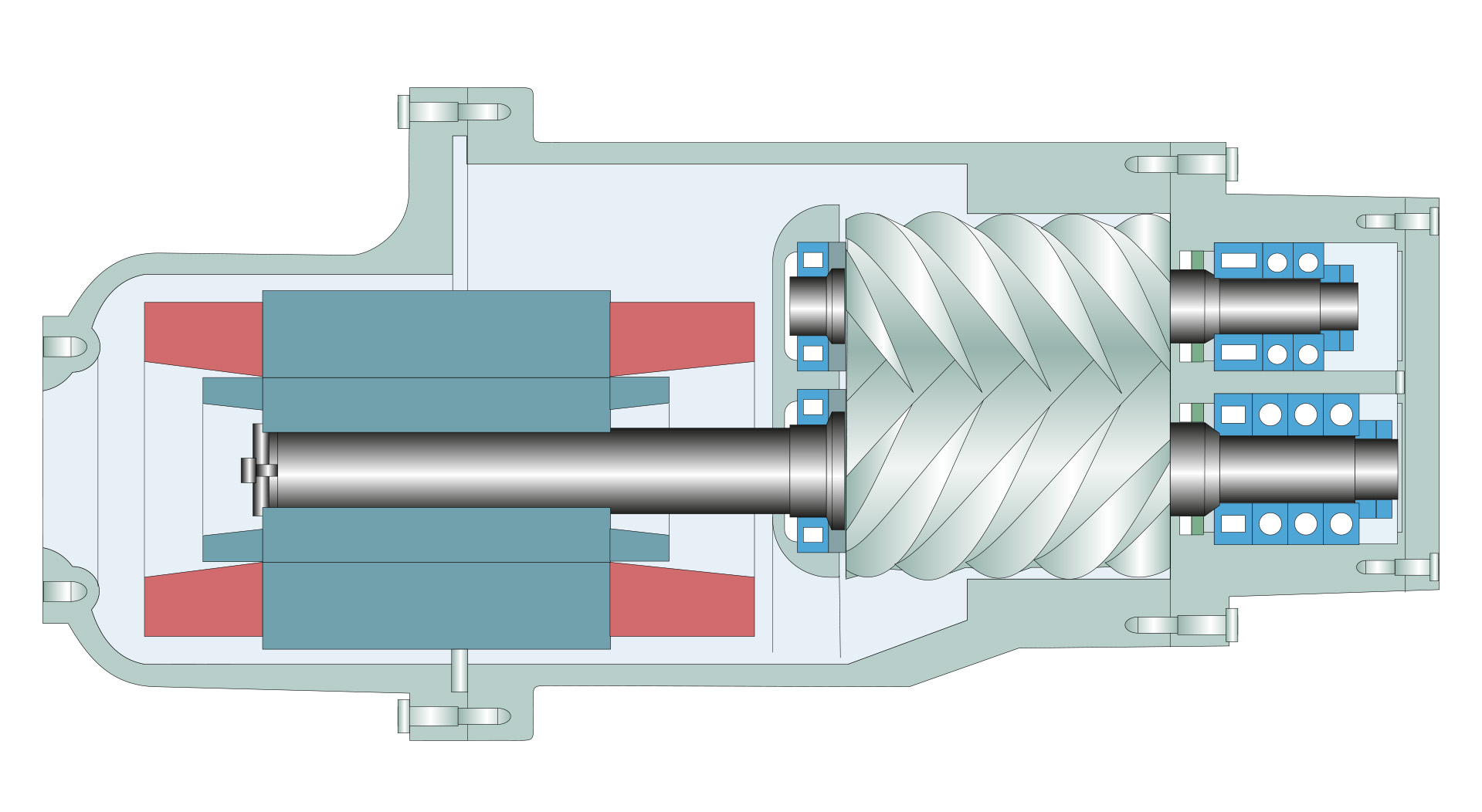

Its essential principles entail compressing the air between two screw rotors. These interlocked rotors feature a specialized matching design, drawing in and compressing the air before propelling it towards the discharge point. Utilizing the gearbox power transfer feature, the rotors rotate synchronously, enhancing efficiency and contributing to a more user-friendly system. However, regular maintenance and control are required to ensure the proper functioning of the system. Without regular maintenance and control, the likelihood of failures may increase, leading to a significant reduction in system efficiency. Screw compressors are equipped with a technology that utilizes screw rotors to compress air. These rotors interlock each other and compress the air while rotating. However, the gearbox system plays a critical role in ensuring that this process is done regularly and efficiently.

Definition and Function of the Gearbox System

The gearbox system is a prominently used component in the industrial and mechanical fields. These systems enable the transfer of power and motion machine-to-machine or to various parts within the system. Essentially, gearbox systems are mechanisms comprising of various gear wheels combined. This mechanism can transfer rotational motion along different axes, increase or decrease speed, and alter the direction of rotation. Ultra Series gearbox screw systems, in particular, distinguish themselves with high performance and low noise levels. Ideal for sensitive applications, they typically provide high efficiency and low energy consumption.

- The gearbox system corresponds to a mechanism that facilitates the interlocking of screw rotors. It typically includes an oil-powered gearbox, enabling synchronous rotation of the rotors. This ensures effective energy transfer and a smooth compression.

Operation Principle of the Gearbox System

The gearbox system fundamentally operates by generating a pressure difference between the entrance and discharge. The system is designed to operate at optimal levels, typically at bar entrance pressure and a value of 20. It increases air or gas pressure through gearbox screw compressors. The compressor houses rotating screw rotors driven by the engine, with these rotors synchronized through the gearbox. Hence, energy is transformed into compressed air or gas with mechanical movement. Energy efficiency plays a crucial role in this process. Indeed, the system should operate by utilizing the required energy with minimal loss.

- The gearbox system, delivers a synchronous rotation by interlocking the screw rotors. The system operates smoothly when the gears are correctly positioned, and the oil is circulated regularly. This minimizes energy loss, thereby enhancing the efficiency of the compressor.