What Is Frequency Inverter?

13 January 2023, Friday

Frequency inverter converts frequency. Frequency inverter ensures regular energy current supply to your compressors. This way, you do not encounter fluctuations in your compressor. Today, the biggest factor that shortens the life of compressors is fluctuation of the energy supplied to the compressor. The compressor cannot operate in a stable way with fluctuating energy. The components inside the unstable compressor become damaged. When frequency inverter technology is used, electricity is transmitted to the inverter first. It regulates inverter frequency and decides how much of the electrical power will reach the compressor.

What Are the Advantages of Using Frequency Inverter?

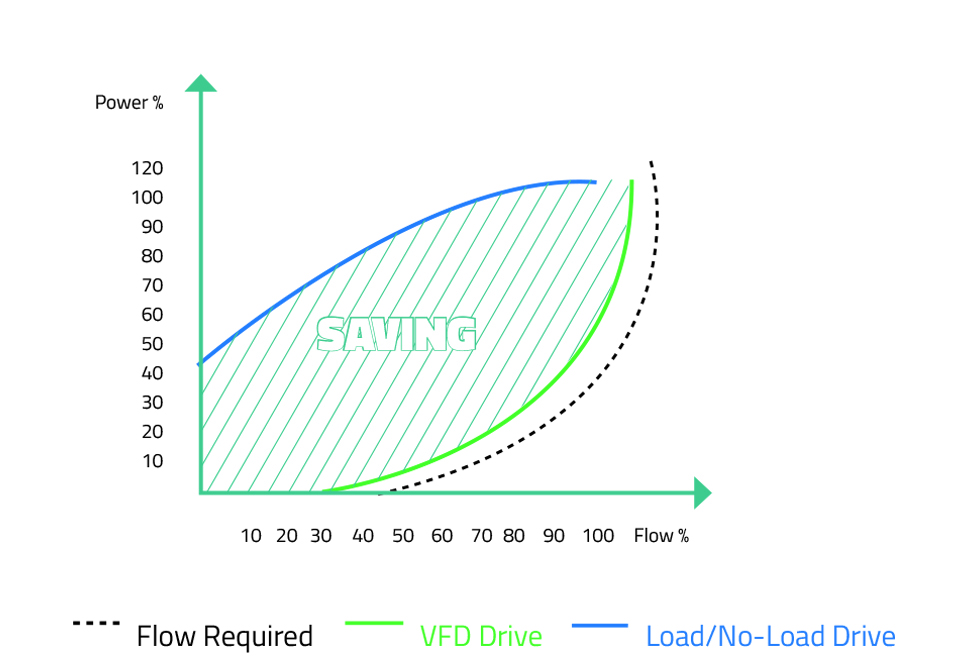

Regulation range of the pressure of the air compressor is wide and less stable. When a compressor is not at its peak, it will run idle and therefore consume excessive energy. Energy waste is a serious issue. The frequency inverter provides maximum energy efficiency even if you are using compressors at low power. Frequency inverter supplies energy based on needs.

Another benefit provided by the frequency inverter is that it supplies energy regularly. Sometimes, the compressor may receive energy irregularly due to problems in the energy source. This irregular energy directly affects the operation of the compressor. However, you will not encounter such a situation if you use frequency inverter in the compressor system. Frequency inverter allows you to use the compressor in the most efficient way by making this irregular energy regular.

Motors are protected by the frequency inverter. Irregular energy to the motor is one of the biggest factors that cause failure. Using frequency inverter ensures long life of motors. Frequency inverter balances low and high-power current to ensure stable operation of the compressor.

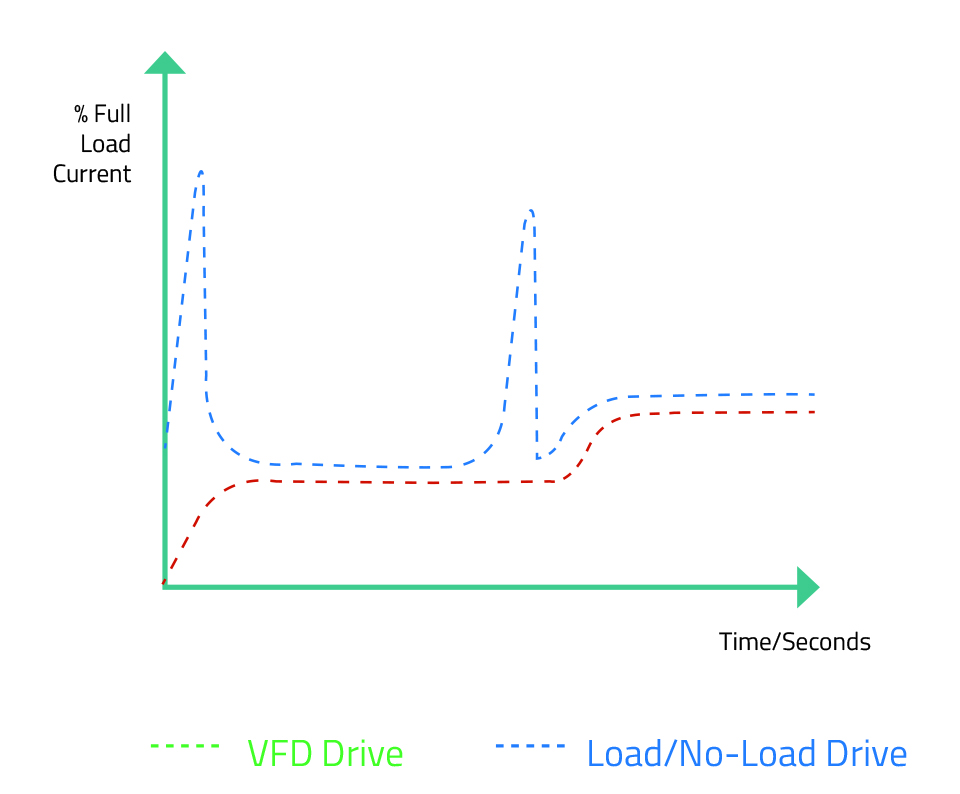

There is an incredible energy consumption during the first start-up of the compressors. This is called the first take-off of the compressor. Motor malfunctions may occur when compressors operating with high energy draw low current at this point. However, frequency inverter is activated at this point. In the first take-off of the compressor, a balanced electricity is drawn thanks to the frequency inverter and the compressor is operated with a balanced energy without the need for high energy. This ensures more comfortable and smooth operation of the compressor. The compressor, which operates smoothly and comfortably at first start-up, wears less. At the same time, it provides a long life of use.

Air compressors get very hot when they operate too hard, when elements such as the oil pump oil filter fail or when they are incorrectly positioned. When it gets too hot, the oil which is naturally inside and prevents friction also gets hot. Oils retain their properties to a certain extent, and after a certain degree, they lose their properties and cause wear of the moving parts. For this reason, when the compressor operates for a long time in summer, oil overheats and loses its properties. Subsequently, the parts inside the compressor corrode each other, and the compressor causes excessive costs. Frequency inverter ensures that your compressor is stopped by taking it under protection when it gets too hot. Therefore, the oil inside does not lose its properties.

The pressure needs of the production enterprises change during the day in general. Compressors operate under load-idle mode in order to fulfil these changing pressure needs. Although the compressor operating in idle mode does not produce any air, it consumes approximately 30-35 percent of the installed engine power, thus causing energy consumption. Frequency inverter detects the instant air need of the enterprise, adjusts the motor speed according to this need, and thus provides 35 percent energy savings. It can respond to different pressure needs with changes to be made on the control panel without making any changes to the compressor.

Variable Frequency Drive (VFD)

In manufacturing facilities, the need for air tends to fluctuate throughout the day for various reasons. Standard compressors continuously work in load/unload mode in order to satisfy changing air demands. A screw compressor working in unload mode spends about 30-35% of the installed motor power and wastes energy even though it does not produce any air.

In OSC V, OSC D, OSC DS and OBS D series compressors, the built-in frequency inverter adjusts the motor speed according to the actual air need of the facility. Achieving energy savings of up to35%, these compressors help reduce operating costs.