Use Of Screw Compressors In The Plastics Industry

24 May 2023, Wednesday

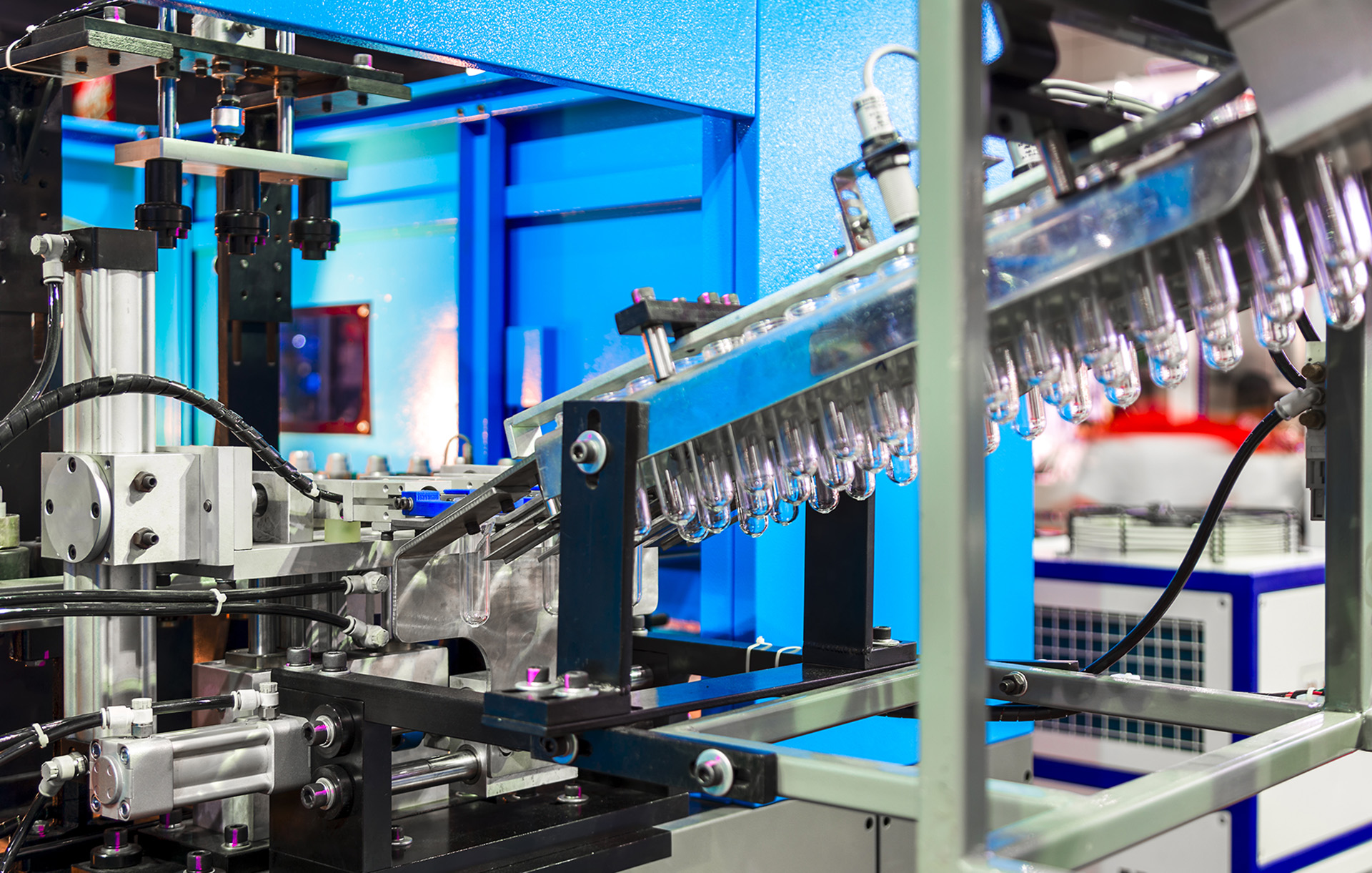

Compressed air plays quite an important role in the plastics industry. Plastic products are shaped by heating the material and then cooling it. The cooling, blowing, and moulding operations utilize compressors and vacuum pumps. Screw compressors are widely used in plastic manufacturing for moulding and other manufacturing services, to power pneumatic tools, and to assist in cleaning tasks.

Use of Screw Compressors in the Plastics Industry

The plastics industry works non-stop 24/7 so the compressed air it uses has to be efficient and interruption-free. Plastics are commonly used in the food and pharma industries, so the compressed air used to manufacture them needs to be of high quality and free of oil residues and other pollutants that could ruin the end product.

Without a doubt, the most important reason for using screw compressors in the plastics industry is the high quality of the air they supply and their energy-efficient operation. Energy consumption is an important criterion for any plant running continuous production. The use of extremely energy-efficient screw compressors helps keep operating costs down and production sustainable.

The other reasons for preferring screw compressors are minimal maintenance requirements, ease of assembly, and long service life.

The Benefits of Özen Screw Booster Compressors for the Plastics Industry

Özen Kompresör’s range of screw compressors is designed to meet all the needs of the industry. The OBS D screw compressors included in this range are ideal for the plastics industry and its continuous production. Able to operate 24/7 without a problem, the OBS D screw compressors provide savings of 10-15 percent in total ownership costs.

The frequency inverter on the OBS D booster compressors provides energy savings of up to 35 percent by adjusting the motor’s RPM according to the business’s actual air needs at any given moment. Operating at between 10 and 40 bars, screw compressors offer solutions that reduce shrinkage loss when inflating PET in the plastics industry.

Screw booster compressors require first maintenance after 8,000 hours and have the benefit of 50-percent lower maintenance costs. 21 sensors placed at various critical sections monitor all the functions of the OBS D booster compressors while the electronic control system prevents possible problems.

Please contact our sales engineers to help you choose the right booster compressor for your business.