Operating Principles and Characteristics of a Screw Type Compressor

17 July 2023, Monday

Screw type compressors are powerful compressed air systems used in industrial applications and designed to compress air. This equipment is widely used in order to increase the energy efficiency of businesses, optimize production processes and reduce costs. Screw type air compressors intake and compress air and store it under high pressure. Thus, they are widely used in many industries.

Operating Principle of a Screw Type Compressor

The working principle of a screw type compressor is quite simple. Two screw rotors are used in screw type air compressors to compress the air. These rotors rotate in perfect synchronization with each other, drawing in and compressing the air. The first rotor draws air into the compressor, while the second rotor compresses the air and builds up higher pressure. This process is repeated in a continuous cycle and resumed until the desired pressure is reached. Screw rotors increase pressure while reducing air volume thanks to the threaded profile of the screws. At this stage, the heat generated by compressing the air is removed from the compressor and thus cooling is realized. As a result, screw type compressors provide clean compressed air with high pressure.

The operating principle of the screw type compressor ensures that the air flow is continuous and smooth. And this means higher efficiency, lower vibration, and a quiet operation. It is also known that multiple screw rotors are used to increase the capacity of screw type air compressors.

Characteristics of Screw Type Compressors

Some of the characteristics of screw type compressors are as follows:

1. High Efficiency

Screw type air compressors offer excellent performance in terms of energy efficiency. Well-designed screw type compressors operate cost-effectively and efficiently by minimizing energy consumption. In turn, this reduces energy costs and minimizes environmental impacts.

2. Continuous Air Flow

Screw type compressors provide a constant and continuous flow of air. This feature is ideal to fulfil the requirement for constant flow of compressed air in industrial applications. Continuous air flow ensures that production processes run efficiently and without interruption.

3. Low Maintenance Costs

Screw type air compressors are notable for their low maintenance costs. Constructed from components that are built to last in general, screw compressors do not require regular maintenance and can operate smoothly for a long period of time. This reduces operating costs and improves operational efficiency.

4. Extended Service Life

Screw type compressors have a robust construction, and this provides them with a long service life. Screw type air compressors made of quality materials provide advantages in terms of durability. Their long service life reduces the need for costly refurbishment or replacement operations.

Benefits of Screw Type Compressors

Screw type compressors offer many advantages in industrial applications. Here are some advantages of screw type air compressors:

- Higher air efficiency and lower energy consumption

- Provision of continuous airflow and constant pressure

- Lower vibration and noise levels

- Longer uptime and lower maintenance requirements

- Flexible use and easy installation

- Easier integration with automated control systems

- Possibility of customization to suit different capacity and pressure requirements for various industrial areas.

- Compact design for a smaller footprint and easy installation

Areas of Usage for Screw Type Compressors

Screw type air compressors have a wide range of applications in many industrial sectors. Here are some industries where screw type compressors are commonly used:

Manufacturing Industry

Screw compressors are widely used equipment in the manufacturing industry. Air supply in manufacturing processes is vital for the proper functioning of many machines and equipment. In this field, screw type air compressors offer a continuous and uninterrupted air supply while saving energy.

Food and Beverages Industry

Hygiene is an important factor in the food and beverages industry. Screw type compressors are an ideal choice to satisfy the hygiene standards in air supply systems used during food production. They also improve production processes by supporting the maintenance of equipment used in food production.

Automotive Industry

Automotive industry requires high air pressures. Screw type compressors are notable for their capability to provide high-pressure air for different applications used in automotive production. In many automotive processes such as spray painting, brake systems and tire production, screw type air compressors are frequently the first choice of compressed air systems.

Energy Industry

The energy sector has critical processes such as the generation and distribution of power. Screw type compressors provide efficiency in this industry by being employed in power plants and gas transmission systems. Compressed air is used in many processes in the energy industry and screw type compressors are ideally suited to meet this requirement.

Chemical Industry

The chemical industry requires various chemical processes and stages of production. Screw type compressors are widely used in this industry for compressing, mixing, and transporting gases. They provide a reliable air supply and improve productivity in the chemical processes.

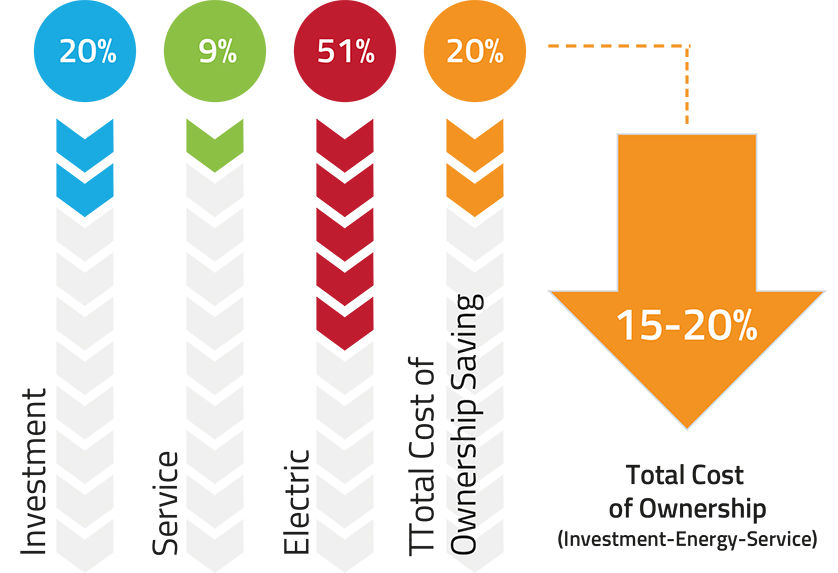

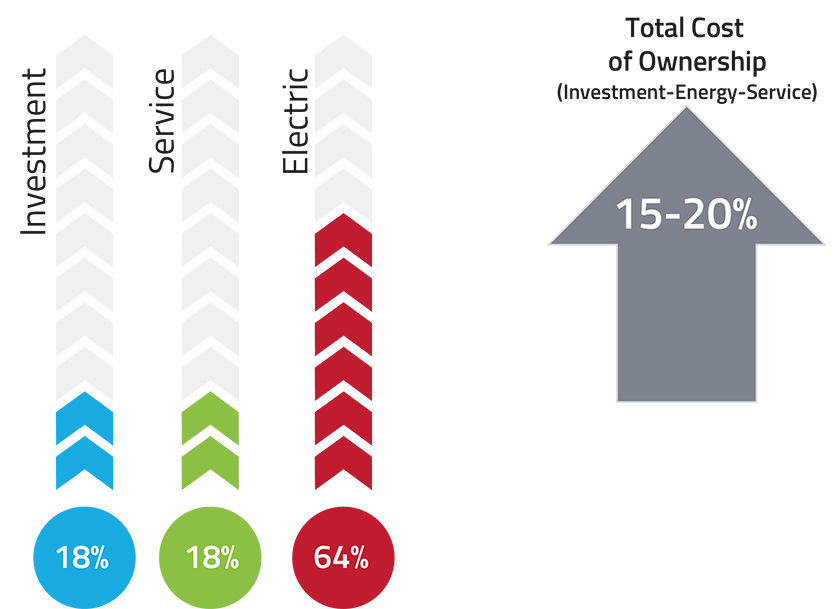

Energy Efficiency of Screw Type Compressors

Screw type air systems use a pair of rotors to compress the air. These rotors, in contact with each other, compress the air and direct it to the outlet port. In this process, screw type compressors provide higher efficiency than other types of compressors. This is because the screw type air compressors operate continuously and compress the air with less energy loss.

Screw type compressors offer high performance at low speeds and save energy. Moreover, the state-of-the-art control systems used in screw type compressed air systems optimize energy consumption by operating based on the air demand. Thus, businesses spend less energy and are able to reduce their costs.

The energy efficiency of screw type air compressors is also an advantage for long-term use. Because screw type compressors have low operating temperatures, and this means less energy consumption. Furthermore, special coatings and insulation materials used in screw type air compressors minimize the loss of energy and improve performance.

SCREW BOOSTER

PISTON BOOSTER