How to Remove Contaminants from Compressed Air?

25 March 2024, Monday

Are you struggling with dirty and inefficient compressed air in your industrial or manufacturing environment? In the comprehensive guide, we will explore the best tips and techniques to keep the compressed air system clean and running at peak performance. Whether you are dealing with particles, moisture, or oil, there are solutions for you.

Compressed air filter cleaning may sound like a daunting task, but with the right information and tools, it can be a simple process. We will cover everything from understanding the importance of clean compressed air to how to clean and maintain your system.

Why is Air Compressor Cleaning Important?

Compressed air is widely used in various industrial applications, such as retrofitting pneumatic tools, operating machinery, and even food processing. However, air quality, such as compressor filters, is often ignored, which leads to problems such as reduced equipment life, lower efficiency, and compromising product quality.

Air contaminants such as particles, moisture, and oil can have harmful effects on compressed air compressor performance. These contaminants can clog filters, valves, and other components, which can lead to increased pressure drops, reduced airflow, and higher energy consumption. In addition, moisture and oil can cause corrosion and damage to equipment, resulting in costly repairs or replacements.

Maintaining clean compressed air is critical to ensure optimal system performance, minimize downtime, and protect your investment.

It not only improves the reliability and efficiency of your equipment but also helps you meet quality standards and regulatory requirements. Now, let's take a closer look at the common pollutants found in compressed air and their effects on system performance.

Common Contaminants in Compressed Air Compressor

Compressor filters can contain various pollutants that can compromise their quality and efficiency. Understanding these pollutants is the first step in cleaning and maintaining a compressed air filter effectively. Here are the most common pollutants you may encounter:

- 1. Particulate Matter: Particles such as dust, dirt, rust and debris can enter the compressed air system through the intake air or the surrounding environment. These particles can range from invisible microscopic particles to large particles that are visible to the naked eye. Particulate matter can cause blockages, clog filters, and damage sensitive equipment components.

- 2. Humidity: The air naturally contains moisture. When the air is compressed, the moisture condenses and leads to the formation of water droplets. Excessive moisture in the compressed air can cause corrosion, damage pneumatic tools, and affect the consistency and quality of the final product. In addition, moisture can contribute to the growth of bacteria and other microorganisms in the system.

- 3. Oil: In some applications, oil is deliberately incorporated into the compressed air system, for example, as in lubricated air compressors. However, in many cases, oil contamination is undesirable, and leaks can occur through inadequate maintenance or insufficient filtration. Oil can have a negative impact on the performance of pneumatic equipment, contaminate the final product, and pose a health risk in certain industries, such as food processing.

Now that we have identified the common pollutants in compressed air, let's start exploring cleaning methods.

Cleaning Methods for Compressed Air Systems

Cleaning a compressed air system involves removing pollutants such as air particles, moisture, and oil, and is important to ensure that the air for your applications is clean and safe. The cleaning method you choose will depend on the presence of certain pollutants and the level of cleaning required. Some common cleaning methods for compressed air systems are:

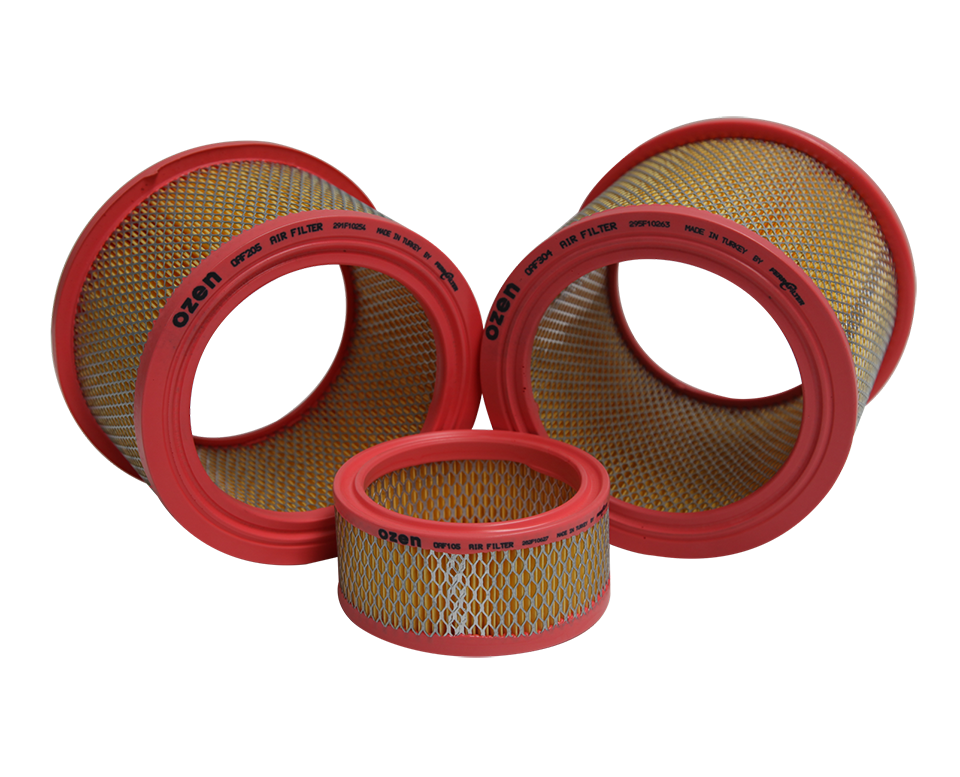

- 1. Compressed Air Filter: Filtration is one of the most common and effective methods for removing particulate matter from compressed air. Filters are used to capture and remove particles of different sizes by placing them at different points. Coarse filters are often used as the first line of defense to remove larger particles, while finer filters are used to trap smaller particles. Checking and changing filters regularly is important to maintain their effectiveness.

- 2. Drying: Various drying techniques can be used to remove moisture from compressed air. Refrigerated air dryers use cooling and condensation to remove moisture while using dryers allows moisture to be trapped. The selection of the appropriate drying method depends on factors such as the desired dew point, system capacity, and energy efficiency requirements. In addition, drain valves must be installed to remove the accumulated water from the system. In addition to these, chemical dryer sets also ensure that moisture and oil inside the system are trapped.

- 3. Degreasing: If your application requires oil-free air, it is extremely important to remove oil pollution from compressed air. Degreasing methods include Kohlesen filters, adsorption filters, and activated carbon filters. Kohlesen filters separate air and oil, collecting oil droplets and allowing them to combine into larger particles. Adsorption filters and activated carbon filters adsorb and trap oil molecules, allowing clean air to escape.