How to Choose the Right Chiller?

25 July 2024, Thu

Following the Industrial Revolution, the role of technology has significantly increased in industrial production processes. In these processes, where production downtime due to excessive heat is not an option, the use of chillers is of vital importance. Chillers emerge as a critical component in various industrial sectors to ensure the safe and efficient continuation of production procedures. It is a well-known fact that chillers keep production lines running continuously in many industrial segments such as chemicals, food, pharmaceuticals, plastics, and metal processing. Recently, the concept of chillers has gained momentum in efforts to enhance energy efficiency and minimize environmental impact. The advantages and innovations that chillers offer in industrial applications are crucial for the quality and sustainability of production.

What is a Chiller?

A chiller is a cooling machine that addresses the cooling requirements of large-scale facilities, utilizing principles of heat transfer. It transfers heat to the environment using a cooling system, thereby reducing ambient temperature. This equipment is essential for energy plants, industrial facilities, shopping malls, hospitals, and other large structures alike. Chiller systems are preferred solutions in such facilities due to their efficient operation and high capacity. Chillers optimize energy consumption and enhance operational efficiency in environments with high-heat generating equipment.

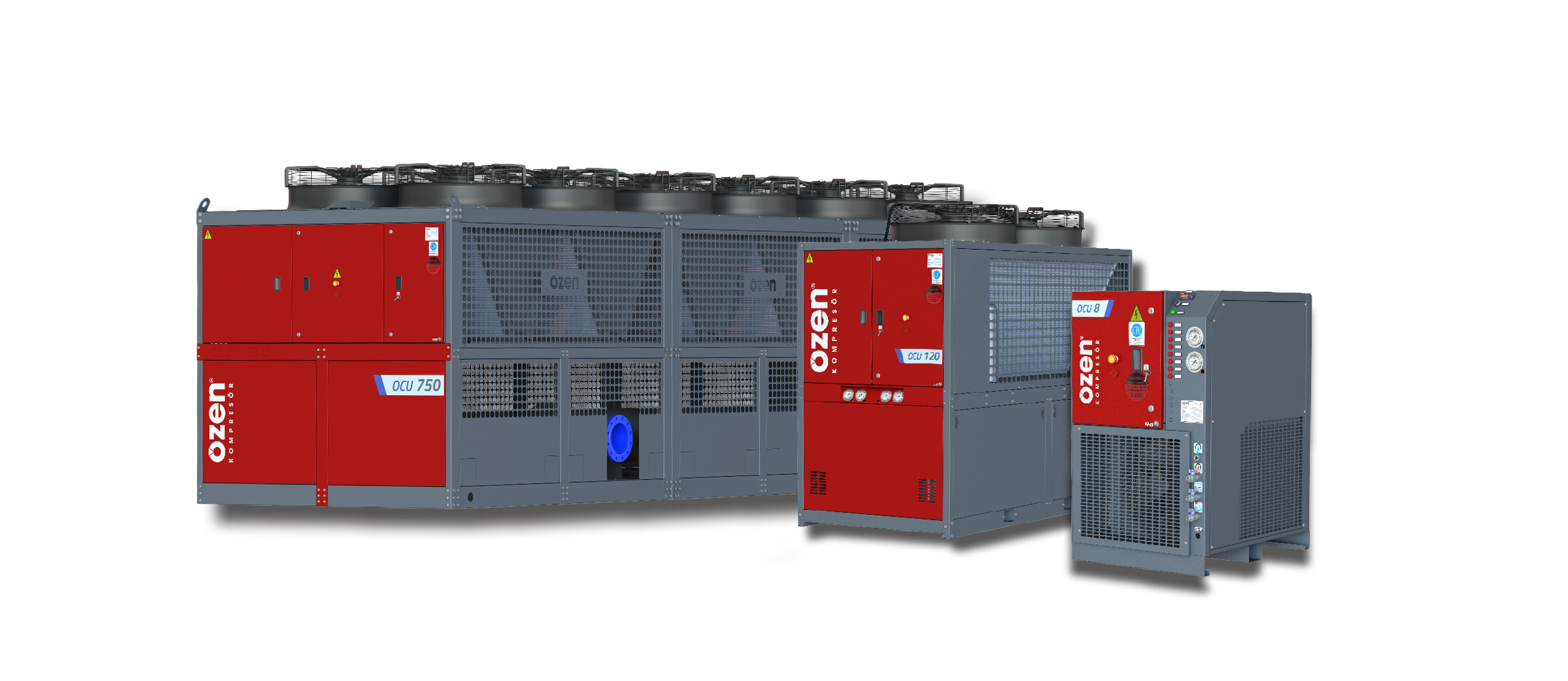

Air-Cooled Chillers

The use of various techniques is crucial in meeting industrial and commercial cooling needs. Air-cooled chiller systems offer practical solutions in cases where aesthetic and environmental conditions or water access restrictions exist. These systems distinguish themselves by relying on air flow for heat transfer, as compared to both air-cooled and water-cooled units. Today, these systems are preferred in spaces such as large buildings, manufacturing facilities, and data centers for their high efficiency and low maintenance costs, offering long-term benefits to businesses. Air-cooled chillers, offering significant advantages in energy efficiency and environmental sustainability, have become an indispensable part of modern cooling solutions.

Water-Cooled Chillers

Water-cooled chillers perform thermal energy transfer during water circulation and cooling processes, effectively removing heat.

They operate together with cooling towers to minimize energy consumption and boost overall system efficiency. They also have the capacity to meet extensive cooling needs, making them commonly utilized in large-scale facilities.

They can be manufactured with various designs and techniques, incorporating key components such as compressors, evaporators, and condensers. Water-cooled chillers generally require more maintenance compared to air-cooled chillers, but this results in longer lifespans and lower operational costs.

They are frequently chosen for large buildings, hospitals, shopping malls, and industrial facilities. Water-cooled chillers are important for their efficiency and extended lifespan, offering economic and environmental advantages.

This system contains following essential elements:

- Coolers

- Condenser water pumps

- Cooling towers

- TES reservoirs

- Water pumps

Why is it important to choose the right chiller?

Selecting the right chiller is crucial for the efficient operation of industrial facilities. One of the most compelling reasons for chiller installation is to effectively remove heat from valuable and temperature-sensitive process equipment used in production processes. Choosing the right chiller minimizes downtime with its continuous protection and ensures uninterrupted production. It also delivers more sustainable and long-term solutions than other cooling methods. A factory may not always meet its cooling needs with its own water supply alone. Thus, when the right chiller is chosen, process efficiency increases and water resources are saved. This also offers significant advantages in terms of energy efficiency. This helps reduce operating costs, leading to economic gains.

Note following considerations when determining and comparing Air and Water Cooled Systems:

|

Specifications |

Air-Cooled Assemblies |

Water-Cooled Assemblies |

|

Outdoor Temperature Increase |

Every 1°C rise in outdoor air temperature leads to a 1% decrease in capacity and a 1% increase in power consumption by the compressor. |

This effect is less apparent in the water-cooled assemblies. |

|

Altitude Increase |

The capacity decreases as the altitude increase. (This is about 1% in Ankara.) |

The impact of altitude increase is lower. |

|

Cooler Replacement |

Replacing R22 with R134a reduces capacity by 32%, but can improve COP due to lower power consumption. |

This is less apparent in the water-cooled assemblies. |

|

Compressor Power Drawing |

- |

Compressors draw 17-37% less power compared to air-cooled assemblies. |

|

Total Power Drawing |

- |

All pumps including tower fans draw 17-30% less power. |

|

COP Value |

- |

COP values are 30-60% better. |

|

Condensation Pressure |

- |

25% lower than air-cooled assemblies. |

|

Weight |

- |

22-35% lower than air-cooled assemblies. |

|

Projection Area |

- |

%70 lower than air-cooled assemblies but still requires a tower. |

|

First Investment Cost |

Lower. |

When towers, tower pumps, tower thermostat, and additional installation materials are added, capacities can increase, typically by around 10%. |

|

Economy by Capacity Increase |

As capacities increase, operational and initial investment costs may rise. |

As capacities increase, this becomes much more economical for operational and initial investment costs. |

|

Types of Compressors |

Typically piston compressors are used. |

Screw compressors draw 4-30% less power. This is much more apparent in the water-cooled types. Centrifugal compressors are preferred. |

Which one should I buy: Water-Cooled Chillers or Air-Cooled Chillers?

When selecting a chiller, cooling capacity is naturally one of the most important criteria. However, the balance between operating costs and capital costs is equally important. Some customers look at initial costs when making purchasing decisions, but this approach may not always be the wisest choice in the long run.

Water-cooled chillers generally have higher energy efficiency and have the potential to reduce operating costs in large-scale systems. However, these systems typically require high initial investment costs. Air-cooled chillers have lower initial costs and may be more logical for small-scale applications.

A value-focused option should be chosen considering both operating and initial costs. In addition to cooling capacity, long-term efficiency and costs are equally important considerations for a system. Thus, the primary guiding principle for selecting these chillers should be based on functional needs and an assessment of long-term total ownership costs.

For each option, relevant advantages and disadvantages should be considered, and a comprehensive cost-benefit analysis should be done.