How to Calculate the Required Air Consumption in the Enterprise?

11 January 2024, Thursday

In enterprises, compressed air is a basic requirement for the operation of many machines and vehicles. However, it is very important to determine and calculate the right amount of air consumption. It must be provided by the compressed air compressor that is required by the enterprise. The required air amount for each machine and vehicle is determined by the nominal air consumption points and calculated as the sum of it.

On the other hand, individual usage factors are also identified and then added to the calculation. Thus, the actual air consumption is determined by considering the leakage, ageing, and other additions. Since each machine and vehicle within the enterprise has different needs, individual usage factors are important.

How Is Compressed Air Consumption Calculated?

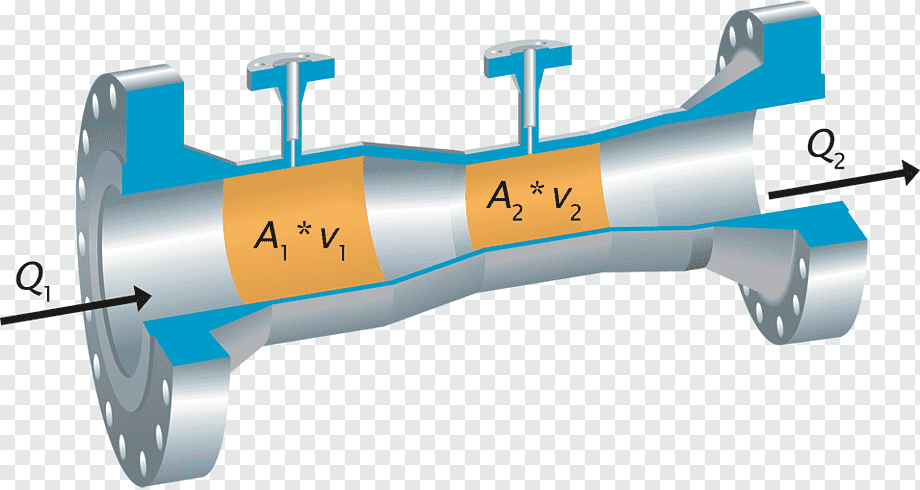

A compressed air consumption calculation requires a facility or machine list and the air consumption data of those machines. Sometimes, if this data is not available, standard values are used. It can be particularly difficult for tools because each tool has a different air consumption. In this case, the calculation values can be determined by referencing the data that are used in similar applications. When calculating compressed air, it should not be confused with consumption, because consumption refers to the air consumption of a machine operating at a standard pressure. In contrast, free air flow refers to pressure loss and reserve capacity. The calculated reserve capacity is primarily required for the control system and the degree of flexibility. Therefore, the calculation of compressed air consumption can be difficult in case the machines do not have specific consumption data; calculations can be made in this scope with data obtained from standard values or similar applications.

First, to calculate your required air, it is necessary to collect a few data points that necessitate measuring the compressed air flow rate and air requirements. How do you calculate compressed air requirements? There are several different methods and tools that you can use, depending on your needs and your system. Some of them require more expensive tools or services than others, while others provide more accurate or long-term results.

Method-1 This approach provides a quick estimate of the compressor capacity and the demand of the system, but it may be less accurate than some other methods. This includes the timing of the compressor's load and unloading cycles and takes into account the receiver volume and load and unloading pressures.

Method-2 This second method is usually more accurate and requires the help of a professional. The professional connects a data logger on the system and collects data for a specific period which is usually a week or two weeks. During this time, it collects data on the current situation, its trends, and any fluctuations that occur.

Method-3 This option provides data that is collected over a long period of time and which is more accurate. This occurs by means of an internal flow meter that records data electronically. You can catalogue this information and then use it for long-term, continuous monitoring and adjustments.

This flow rate can be measured in cubic feet per minute (CFM). However, CFM can vary widely. Air can get trapped and it can change rapidly due to atmospheric changes in air pressure, density, temperature, and more. Location, altitude, and seasons can have an impact on all weather conditions.

Standard CFM (SCFM): To set the pressure differences in different conditions, SCFM makes adjustments to fill a standard cubic meter of air. It measures the weight, not the volume. It makes adjustments for absolute square inch pressure (psia), temperature and relative humidity.

Actual CFM (ACFM): It rates the flow performance with the actual pressure and temperature.

CFM (ICFM): It refers to the inlet flange conditions of the compressor. Generally, an inlet filter causes the air pressure to drop when air is pulled in and compressor vendors have to take this into account to estimate the performance accurately.

Finally, you will need to do the enterprise analysis, where you need to produce an optimal level of compressed air. You can find the air consumption data and expected utilization factors of all your machines. Measure them during normal operating procedures that represent your typical habits, during a suitable period of at least a week, but it's always better to obtain exact numbers from your equipment.

We'll start by creating a demand profile to find out the required air amount. List the demands of your machine based on the manufacturer's methods. This information should include the required pressure and operating flow rates, and peak and average conditions. Intermittent requests are also helpful.

How Is Air Consumption Measured?

First, compressor capacity must be analysed. Compressor's operating hours cannot be read from its counter; so, it may be necessary to decrease compressor usage at certain times with the changes in production. When it is operated at an optimum pressure, it can provide efficient air; so, the amount of the compressor must also be taken into account. For a facility with changing air requirements, the amount of compressor must be changed to meet the current conditions. Also, factors such as loading times and loading and unloading times must be taken into account. By taking into account all these factors, required steps can be taken for optimal air consumption.