How Inlet Air Temperature Affects Your Compressor’s Airflow

28 April 2025, Monday

When building your own air compressor system or acquiring a pre-existing one, it's crucial to carefully consider the position of the air intake. This location directly affects the quality and efficiency of compressor performance. One of the most critical factors influencing this efficiency is the temperature of the incoming air. A mere 3°C increase in temperature can lead to about a 1% rise in energy usage—significantly impacting your annual operating costs. In addition, hot intake air can reduce compressor capacity and shorten the lifespan of system components. In industrial settings, even slight fluctuations in intake air temperature can affect production efficiency and equipment durability.

Why Do Rising Temperatures Reduce Compressor Efficiency?

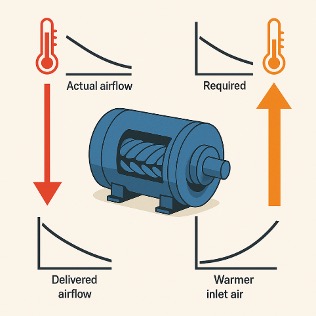

Most air compression machines operate on displacement-based systems that naturally draw in ambient air, making environmental conditions vital to their performance. The intake air enters the device based on the ambient temperature and pressure; however, climatic changes and rising environmental temperatures can negatively affect this process.

As air temperature rises, its density decreases—an essential physical law that directly affects how the compressor functions. Since compressors take in a fixed volume of air, decreased density means less mass of air is compressed per cycle. Even though the same amount of energy is consumed, the result is less air output. Technically speaking, the maximum air a compressor can draw in per stroke is defined by the cylinder’s volume at the bottom dead center. Warmer air means fewer air molecules enter that space, reducing efficiency and increasing energy consumption. Studies show that lower ambient temperatures can improve air delivery by approximately 3%.

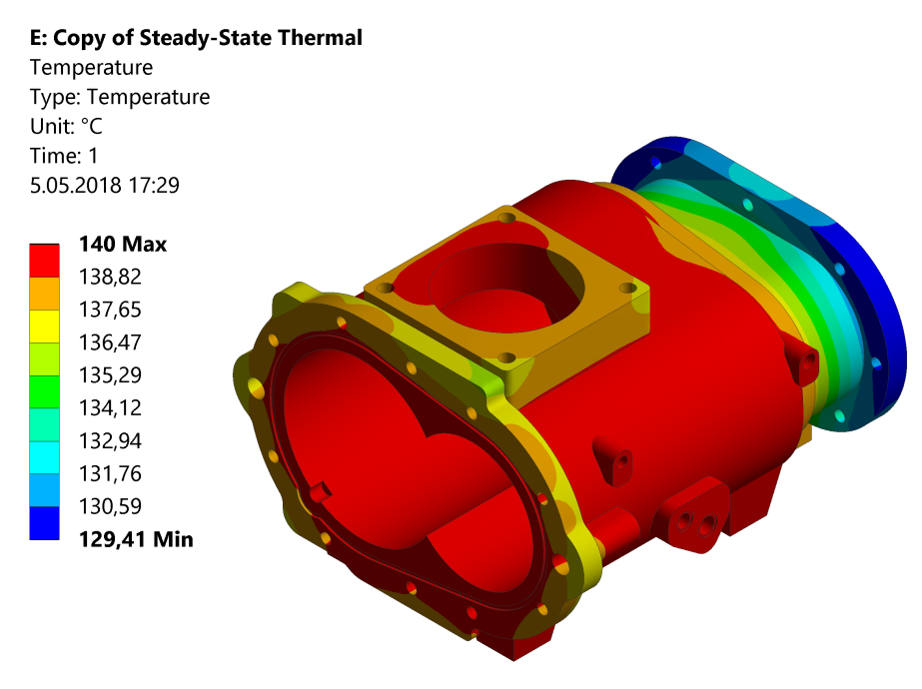

Impact of Inlet Air Temperature on Compressor Performance

Industrial air compressors are influenced not only by mechanical and design factors but also by environmental variables. Among them, inlet air temperature plays a direct role in efficiency and energy consumption. Below is an analysis of how inlet temperature affects three main types of compressors:

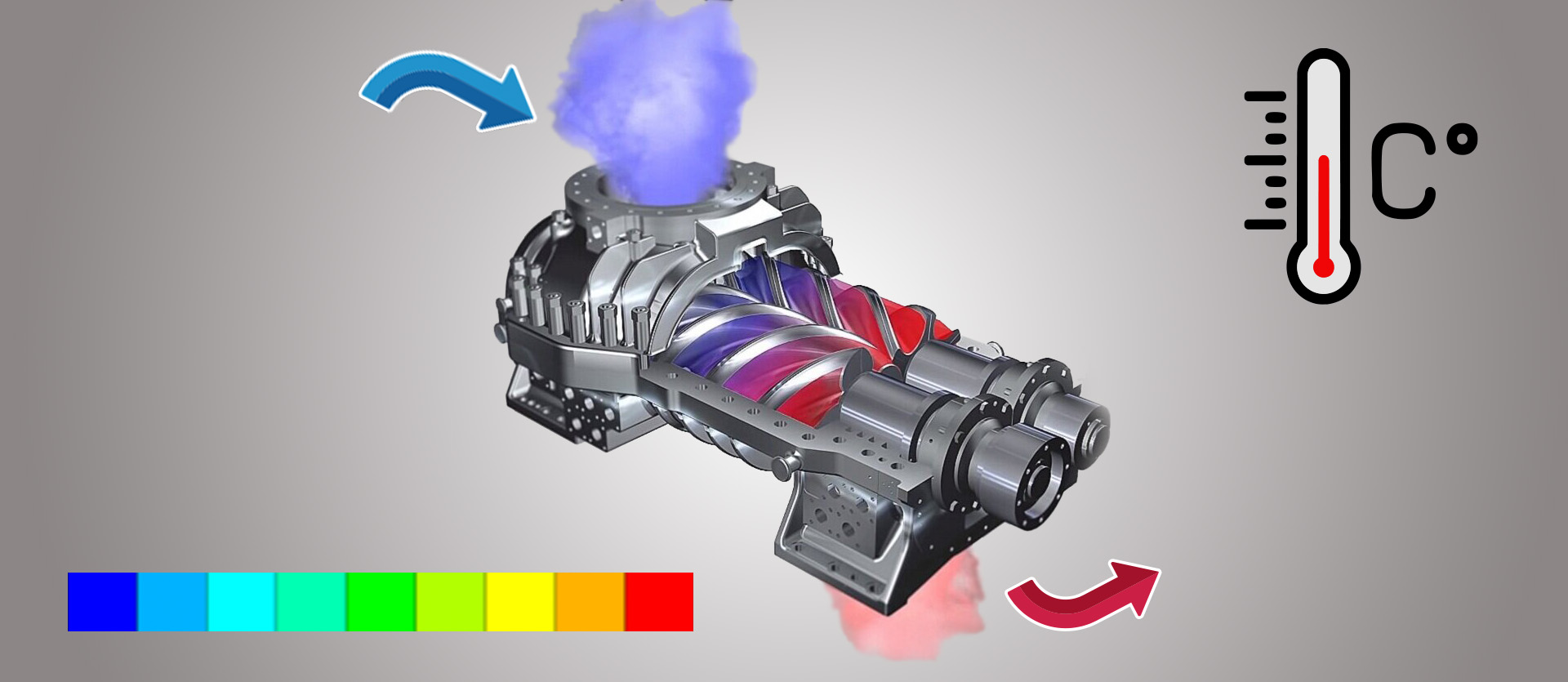

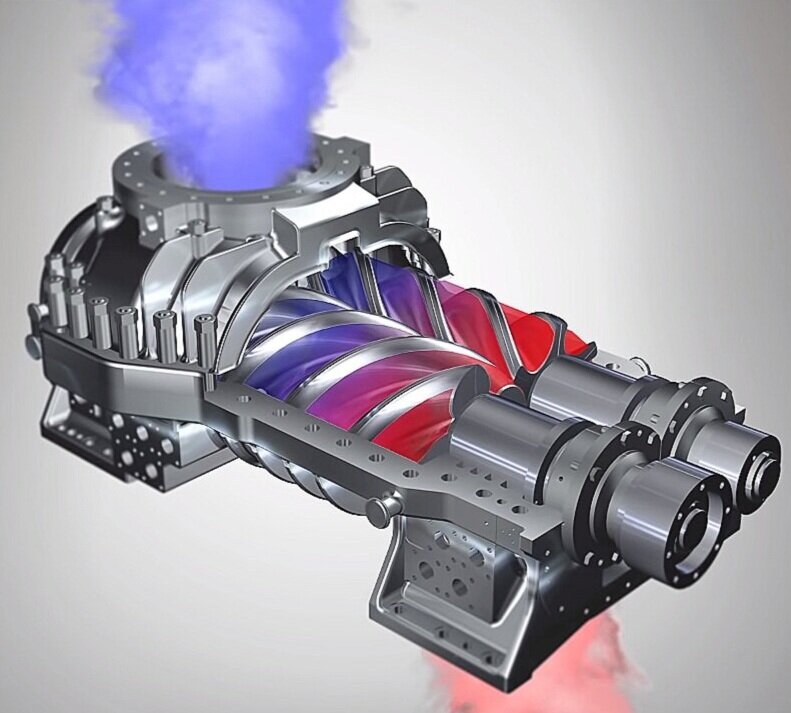

- 1. Oil-injected screw compressors

- 2. Oil-free screw compressors

- 3. Multistage centrifugal compressors

How Much Does Air Density Matter?

Air density varies with temperature, significantly affecting engine performance. For example, if a compressor pulls in 60°C (140°F) air, the density is around 1.05 kg/m³, offering less oxygen than needed, leading to poor performance. But if it draws in air directly from a cooler environment like 15°C (59°F), the density increases to 1.225 kg/m³, providing more oxygen and potentially boosting motor output by up to 17%. This not only enhances performance but also reduces fuel consumption.

Key Airflow Units: ICFM vs SCFM

ICFM (Actual Cubic Feet per Minute): Measured under actual conditions at the compressor inlet; unadjusted for environmental factors.

SCFM (Standard Cubic Feet per Minute): Adjusted to standard conditions (14.7 psi, 68°F, 36% relative humidity); reflects true air consumption.

Thermodynamic Compression Models

Adiabatic (Isentropic) Compression: Compression occurs without heat exchange. Temperature rises during the process. Common in oil-free screw compressors.

Isothermal Compression: Ideal model where temperature remains constant due to continuous heat dissipation. Seen in oil-injected screw compressors.

Volumetric Efficiency: Ratio of actual air intake to theoretical maximum. Leaks and slippage can reduce this efficiency.

Effects by Compressor Type

Oil-Injected Screw Compressors

This type of compressor provides both sealing and effective cooling thanks to the oil injected inside. Therefore, the temperature increase during the compression process is more limited.

- ICFM: Constant regardless of inlet temperature.

- SCFM: Increases with cooler air intake (e.g., 10°F drop = 1.9% mass flow gain).

- Power Use: Slight increase, but efficiency rises sharply.

Oil-Free Screw Compressors

Used in sensitive sectors like food or pharma where cleanliness is critical. Heat rises faster due to lack of oil.

- ICFM: Remains constant.

- SCFM: Cooler air increases mass flow.

- Power Use: More energy is needed as density rises in adiabatic models.

Critical Notes:

- High intake temps can cause shutdowns due to extreme outlet temps.

- Low intake temps risk condensation, especially in intercoolers.

While SCFM/kW ratio may stay stable, cool air still offers control advantages.

Multistage Centrifugal Compressors

Ideal for large-scale airflow, and highly sensitive to inlet air conditions.

- Pressure Output: Better at low inlet temperatures.

- Flow Rate: Colder air = higher density = more airflow.

- Power Use: Increases with airflow, but efficiency remains constant. → A 20°F change affects efficiency only by 0.2%, but significantly impacts motor load, control, and air distribution.

The Role of Control Systems

To benefit from lower inlet temperatures, effective compressor control systems are essential:

Oil-Injected Screw

- Modulation Control: Can increase system pressure and cause leaks, reducing efficiency.

- Load/Unload: Longer idle times may occur.

- VSD (Variable Speed Drive): Most efficient:- saves energy as intake air cools.

Oil-Free Screw

- Load/Unload: Long idle periods can hurt performance.

- VSD: Provides more stable performance but offers limited efficiency gains.

Centrifugal Compressors

- Inlet Modulation: Must be finely tuned to prevent instability as air temperature drops.

Summary of Efficiency Gains

- Oil-injected screw compressors with VSD benefit the most from cool intake air.

- Other compressor types may see limited or even negative impacts depending on system design and control.

- Strategies to cool inlet air must also consider maintenance ease, oil quality, condensation risks, and motor load limits.