OSC DS Ozen Energy Optimisation

Ozen Energy Optimisation

Since the OSC V series screw compressors with frequency inverter adjust the motor speed according to the actual air need of the facility, high energy use during low-capacity utilization is avoided.

Since the OSC V series screw compressors with frequency inverter adjust the motor speed according to the actual air need of the facility, high energy use during low-capacity utilization is avoided.

The Advantage of Constant Pressure

As the actual air demand is continuously monitored, the air production is steady and pressure is constant in the compressed air-pipe line at all times. Energy loss due to load/unload work modes is avoided. These compressors can respond to different pressure needs with simple settings on the control panel, without changing anything in the compressor itself.

Smooth Initial Start-up

Because motor speed is controlled by the frequency inverter, the initial start-up is significantly simpler and smoother than a wye-delta, direct connected compressors.

Variable Frequency Drive (VFD)

Variable Frequency Drive (VFD)

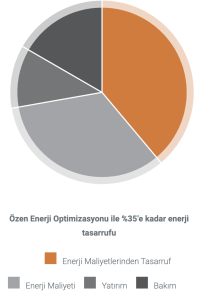

In manufacturing facilities, the need for air tends to fluctuate throughout the day for various reasons. Standard compressors continuously work in load/unload mode in order to satisfy changing air demands. A screw compressor working in unload mode spends about 30-35% of the installed motor power and wastes energy even though it does not produce any air. In OSC V series compressors, the built-in frequency inverter adjusts the motor speed according to the actual air need of the facility. Achieving energy savings of up to 35%, these compressors help reduce operating costs.