OBS D Comparison

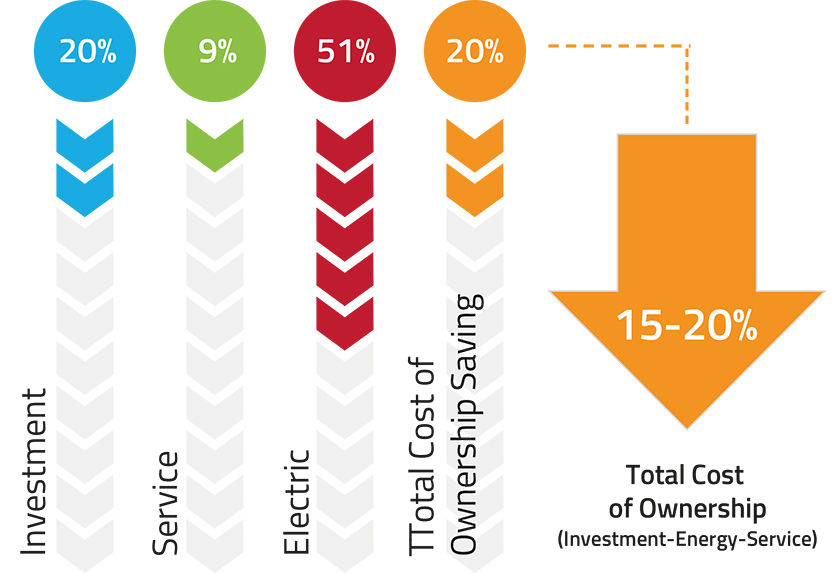

SCREW BOOSTER

- • 10% higher specific power (Full load).

- • 15-20% lower electric consumption. VFD controlled.

- • 8000 h service time. 50% lower service cost.

- • 30% higher OEE. Due to sparse service and maintenance period.

- • 15-20% lower cost of ownership

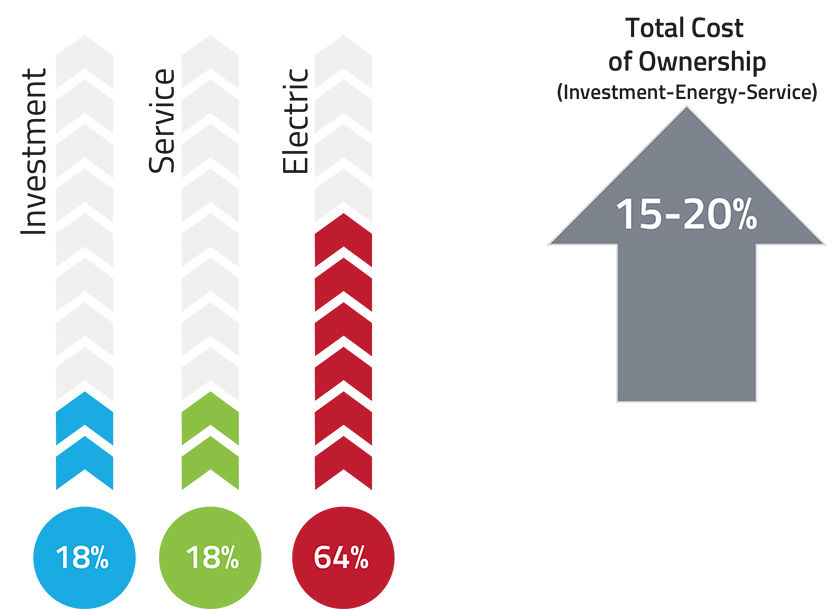

PISTON BOOSTER

- • Lower spesific power due to piston compressing efficency.

- • Works load, no-load with higher electric consumption.

- • Every 2000 h, 4000 h, 8000 h service time.

- • Frequent service and maintenance period