Blog

Kimyasal Hava Kurutucu Nedir ve Nasıl Çalışır?

Fabrika ve atölye gibi üretim merkezlerinde basınçlı hava ile çalışan makinelerin güvenli işleyişi, bazı koşulların doğru şekilde [...]

Pistonlu Hava Kompresörlerinin Özellikleri

Pistonlu kompresörler, havayı sıkıştırarak basıncı artırmak için piston ve silindirini kullanır. Endüstriyel uygulamalar için kullanılan pistonlu kompresörlere, [...]

Kompresörümün Verimini Nasıl Arttırırım?

Verimlilik günümüzde tüm işletmelerin gündeminde olan ve her geçen gün önemi artan bir konu. Enerji kullanımının üretim [...]

Kompresör Soğutma Sistemi

Birçok iş dalında kullanılan kompresör sistemlerinin çalışma prensibi var olan havayı sıkıştırıp basıncını artırarak zor mekanik hareketleri [...]

Kompresör Bakımında Dikkat Edilmesi Gerekenler

Hava kompresörü bakımı, tüm marka ve model kompresörlerde yapılması gereken bir dizi uygulamayı içerir. İster bir ister [...]

Kompresörde Enerji Geri Kazanımı

Yüksek enerji maliyetlerinin ve çevre bilincinin artmasıyla kompresör kullanan işletmeler, bu cihazlarda bulunan potansiyelle ve kullanılmadan dışarı atılan [...]

Azot Jeneratör Kullanımının Faydaları Nelerdir?

Your Content Goes Here PSA Azot Jeneratörleri: Mühendislik Perspektifinden Detaylı İnceleme 1- PSA nedir? Temel prensip [...]

Kompresör Bakımı Ne Sıklıkla Yapılmalı?

Your Content Goes Here Kompresör bakımı, basınçlı hava sistemlerinin verimli çalışması ve uzun ömürlü olması için [...]

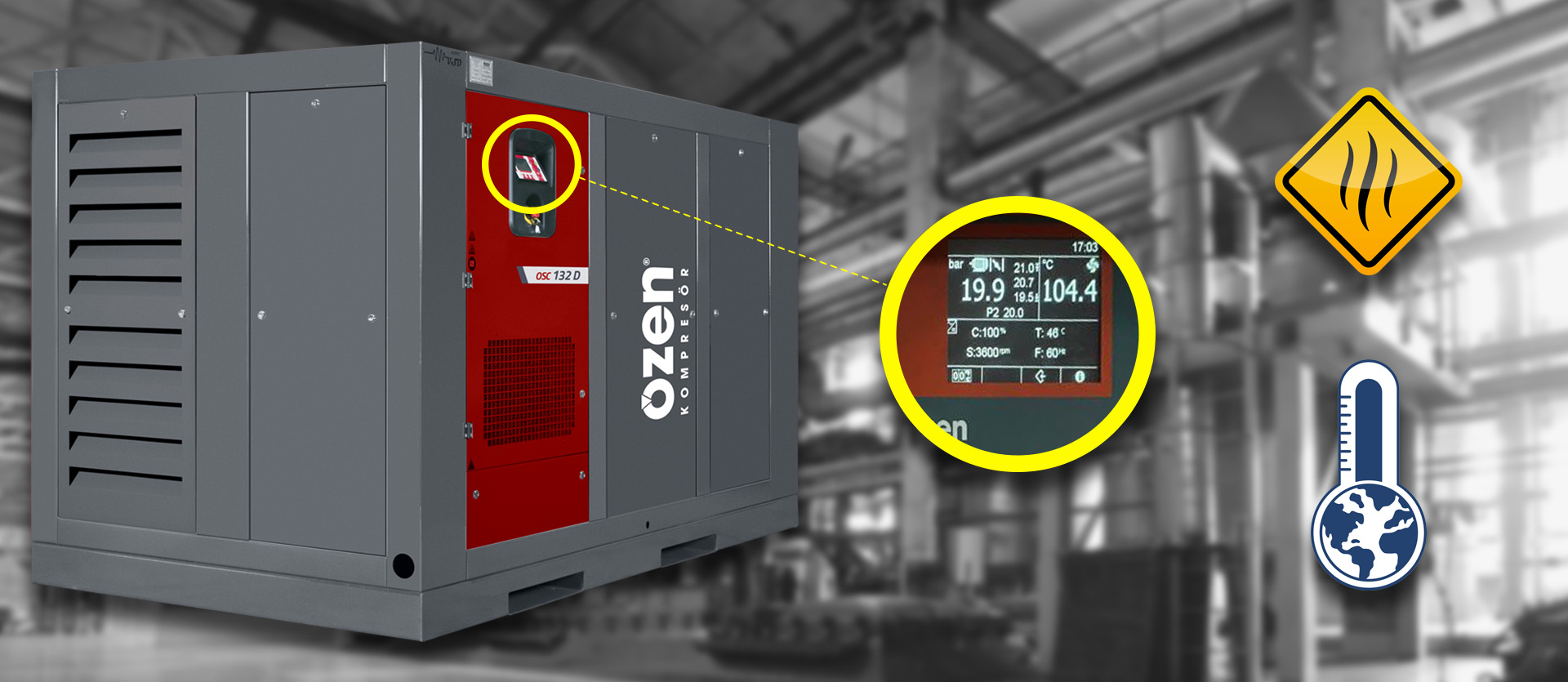

Kompresörlerde Çalışma Sıcaklığının Önemi

Hava Kompresörü Seçerken Bilinmesi Gerekenler Kompresörlerin verimli çalışması, sıcaklık kontrolünün önemini vurgular. Termodinamiğin ilk kanunu, enerjinin [...]

Kompresörde Enerji Geri Kazanımı

Hava Kompresörü Seçerken Bilinmesi Gerekenler Yüksek enerji maliyetlerinin ve çevre bilincinin artmasıyla kompresör kullanan işletmeler, bu [...]

Doğru Kompresör Nasıl Seçilir

Hava Kompresörü Seçerken Bilinmesi Gerekenler Hava kompresörleri çok yönlü makinelerdir ve pnömatik aletlere takıldığında çeşitli görevleri [...]

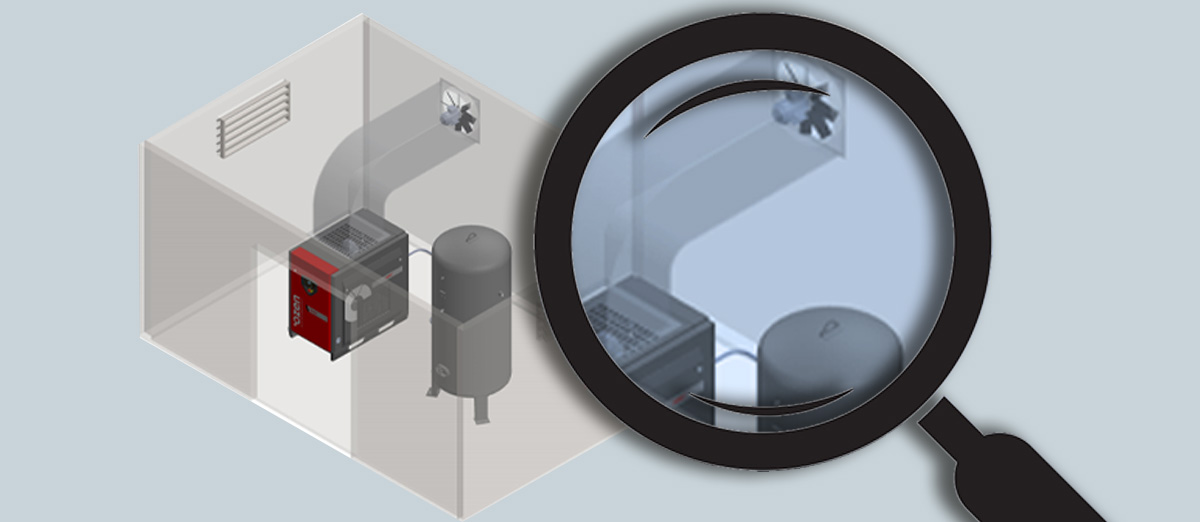

Kompresör Odası Nasıl Olmalıdır?

Basınçlı hava sisteminin verimli bir şekilde çalışması için kompresör odası planlamasının iyi yapılması önemlidir. İşletmelerde kompresör odası [...]