The Importance of Operating Temperature in Compressors

The efficient operation of compressors highlights the importance of temperature control. The first law of thermodynamics states that energy cannot be created or destroyed but can be transformed from one form to another. A motor receives electrical energy from its power source, but due to friction, not all of this energy can be converted into mechanical energy. Compressors are essential equipment used in industrial and commercial applications. They draw in air and compress it, which typically results in higher operating temperatures. This increase in temperature can affect compressor performance and, in the long term, shorten the lifespan of the equipment.

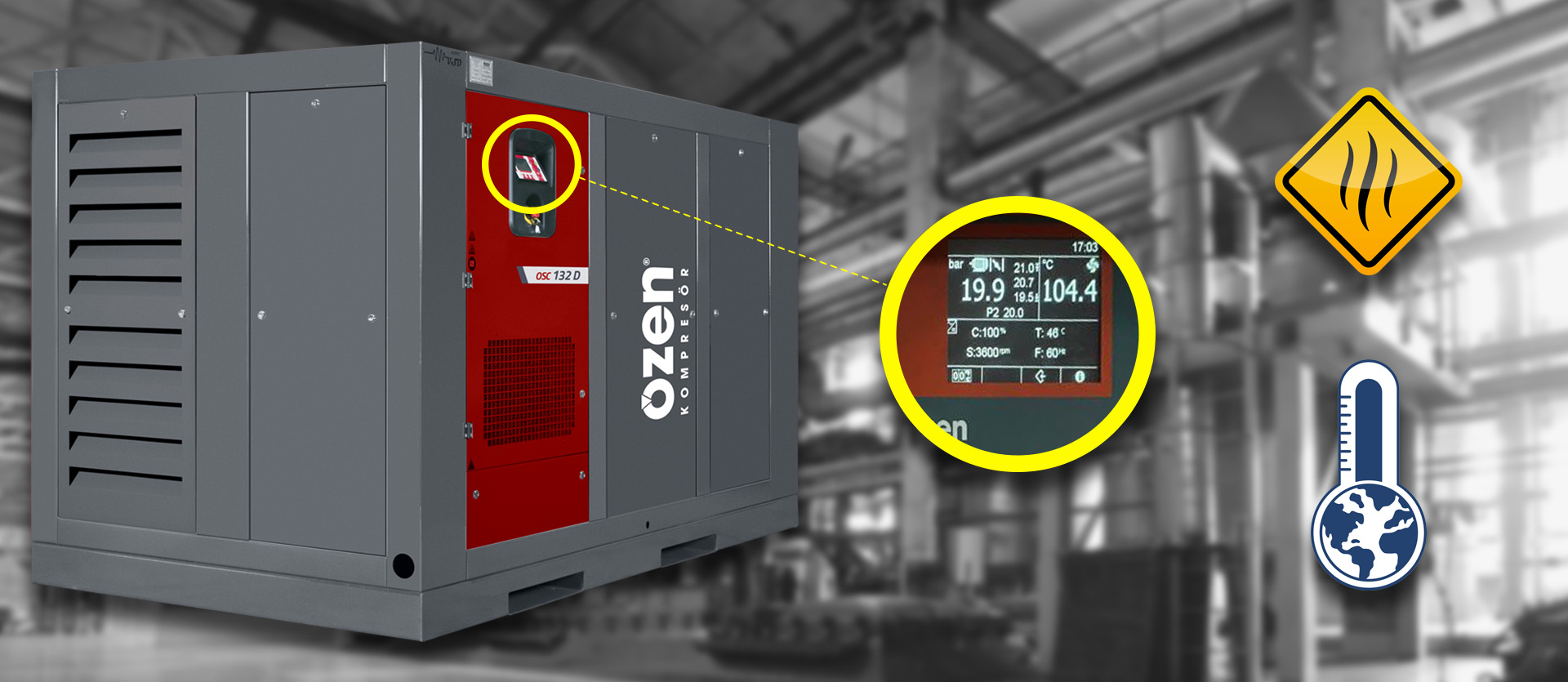

The temperature limit that a motor can withstand significantly affects the efficiency and service life of the compressor. A compressed air compressor undergoes an intense and continuous working process, meaning its motor must withstand high temperatures. Therefore, the operating temperature of the compressor must be determined according to the motor’s capacity and the conditions it is exposed to. High operating temperatures in large industrial facilities can directly impact motor life. Keeping the compressor’s operating temperature under control and preventing it from exceeding the motor’s thermal limits is critical for its efficiency and service life.

Operating Temperature Range of a Compressed Air Compressor

Compressed air compressors can operate within a specific temperature range. Outside this range, the compressor may become uncomfortably hot or excessively cold, preventing it from functioning efficiently. In highly humid environments, condensation inside the compressor may occur beyond the acceptable temperature range, potentially damaging the system. For this reason, maintaining the working temperature of your compressed air compressor within the designated range is essential. Operating outside this range can lead to negative consequences and severe damage.

How Do Compressed Air Systems React to Temperature?

The effects of temperature fluctuations on compressor performance can be surprising. Since these systems are typically used in industrial environments, ambient temperature is a key factor in maintaining optimal air quality. Compressors must be kept within a specific temperature range; otherwise, their performance may decline. Extreme temperatures—either too high or too low—can significantly impact how your compressor operates. These conditions may reduce the compressor’s lifespan or degrade air quality. Therefore, maintaining temperature stability in areas where compressed air systems are installed is crucial.

If your compressor is located outdoors, it will naturally be exposed to drastic temperature changes. However, the operating temperature of indoor compressors can also vary widely if they are placed in areas without climate control or insulation, such as storage rooms. When placing a compressor, you should aim to minimize potential temperature fluctuations in the environment. This helps preserve equipment life, maintain functionality, and prevent costly breakdowns and repairs.

Air Density

Lower air density typically indicates colder air, as cold air cannot hold as much moisture as warm air. This means the air tends to be drier. Less condensation and reduced humidity allow harmful particles to be filtered more easily. As a result, ventilation systems can remove moisture more effectively.

What Is the Best Operating Temperature for a Compressed Air Compressor?

The optimum operating temperature of equipment is often debated among experts. However, most agree that the ideal operating temperature for a compressed air compressor is between 50 and 85°F (10–29.5°C). Within this temperature range, the compressor can maintain its maximum operating temperature, optimize performance, and extend its service life.

If you want to safely manage the heat produced by your compressor, you can vent hot air outdoors via short ducting or redirect excess heat to another area of your facility for reuse. Additionally, to prevent hot air from re-entering the system, any exhaust outlets should be kept as far away from the compressor’s air intake as possible.

Another reason for maintaining the optimal 50–85°F (10–29.5°C) range is humidity. Moisture in air systems is undesirable. While colder air generally contains less moisture, extremely low temperatures can also be harmful. Below certain temperatures, cold air promotes condensation inside the compressor. If the ambient temperature drops too low, this water may freeze and expand, causing internal damage.

For this reason, controlling humidity and preventing freezing are essential to maintaining the ideal operating temperature range. Maintaining the compressor at 50–85°F ensures long service life and efficient performance. Therefore, adhering to this ideal temperature range is crucial for achieving the best performance from your compressed air compressor.