How Often Should a Compressor Be Serviced?

Compressor maintenance is essential for ensuring the efficiency and longevity of compressed air systems. Performing regular maintenance helps prevent potential malfunctions and increases operational efficiency. There are several key elements that must be checked during compressor maintenance.

These include air tightness, oil level, and pressure control. The compressor’s oil and filters should be cleaned and replaced periodically. Over time, the air filter may become clogged, which negatively affects performance.

Compressor maintenance should be carried out by qualified personnel and performed at the recommended intervals. This ensures that the compressor operates safely, efficiently, and with a longer service life.

How Is Periodic Compressor Inspection Performed?

Periodic compressor inspections are crucial to ensure the safe and efficient operation of compressed air systems. These inspections must be conducted at regular intervals depending on the characteristics and usage frequency of the equipment. Periodic inspection helps assess the overall condition of the compressor and detect potential failures before they occur.

During the inspection, pressure levels, air leaks, and other critical parameters are checked. The process also includes observing components to identify wear, leakage, or damage. With periodic inspections, it becomes possible to prevent potential breakdowns and improve the efficiency of the compressed air delivery system. Regular inspections help reduce operating costs and enhance safety precautions, ultimately contributing to longer equipment life.

What Are Periodic Compressor Inspections Based On?

Periodic compressor inspections are carried out to ensure that compressed air systems operate in compliance with health and safety requirements. Compressors play an important role in industrial equipment, and trouble-free operation ensures a safer workplace environment. This inspection process covers all components of the compressor, including electrical connections and the pressure system.

During the inspection, factors such as compressor performance, pressure levels, and airflow are checked, and necessary adjustments are made. This ensures compliance with safety standards and helps prevent workplace accidents. As a result, periodic compressor inspection becomes a key component of workplace safety culture and ensures the smooth operation of systems.

What Should Be Considered When Servicing a Compressor?

There are several critical points to consider when performing compressor maintenance. These include the compressor’s overall condition, filter cleanliness, and oil level and quality. Proper maintenance is essential to ensure safe operation of these machines.

Compressors must be operated in accordance with occupational health and safety standards. Therefore, maintenance procedures should be performed according to the control criteria defined in relevant regulations. Failure to do so may reduce system performance and lead to serious issues.

Compressor Maintenance Tips

Compressor maintenance includes properly adjusting pressure levels, regularly cleaning and replacing air filters, and checking for leaks in tanks and piping.

Dirt and moisture that may accumulate during compressed air production must be detected and removed regularly. Clean air ensures efficient compressor operation and extends equipment life. Additionally, the compressor’s oil level should be monitored and replaced at recommended intervals.

Cooling systems should also be inspected and cleaned regularly. Proper maintenance contributes to safe operation and supports energy-efficient performance.

Professional Compressor Maintenance

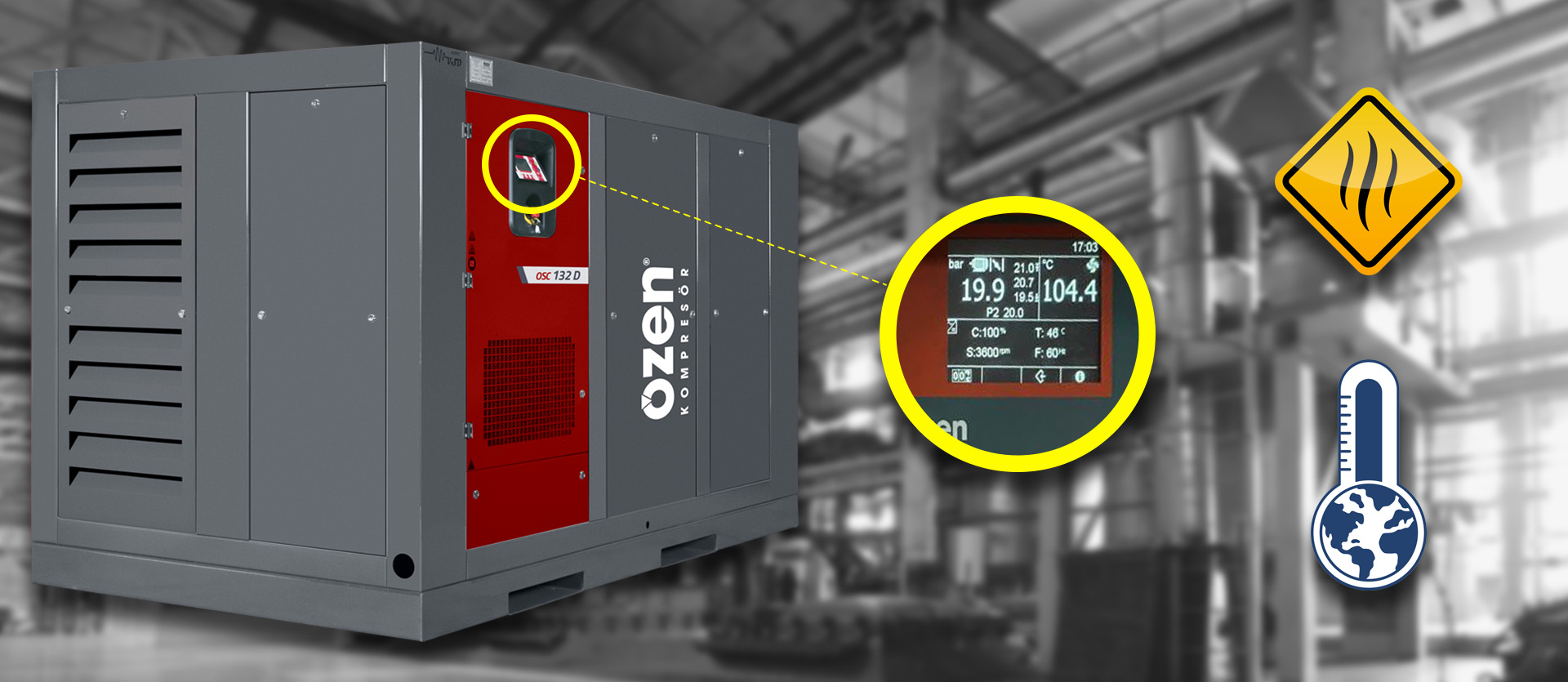

Özen Kompresör provides professional compressor maintenance services. Regular compressor maintenance is crucial for occupational health and safety. Özen Kompresör performs customers’ periodic inspections to ensure compressors operate safely and efficiently. Proper maintenance enhances performance while reducing energy consumption. To avoid operational risks and ensure reliable performance, you can choose Özen Kompresör for expert compressor maintenance.