Energy Recovery in Air Compressors

With rising energy costs and increasing environmental awareness, businesses that use air compressors are becoming more concerned about the potential energy inside these systems and the heat that is discharged unused. During the compression process, the heat generated is removed through a fan or a water-cooled heat exchanger. By recovering 90% or more of the electrical energy consumed to produce compressed air, you can significantly reduce operational costs and benefit from substantial energy savings.

In many production and process applications where heating is required—such as systems powered by electricity, liquid fuels, or gas—some or all of these heating methods can be replaced with the thermal energy recovered from the compressor. The temperature level of the recovered heat determines the potential areas where it can be used.

What Are the Advantages of Energy Recovery in Compressors?

Improving energy efficiency is one of the most essential and vital priorities for all industries. Between 80–90% of the energy consumed by a compressor is converted into usable energy. This usable energy can be recovered as hot water or space heating. If not utilized, it negatively impacts operational costs. At this point, the advantages of installing energy-saving systems can be summarized as follows:

An energy-saving system does not affect compressor maintenance and pays back the investment in as little as one year.

Heat recovery not only reduces energy costs but also contributes to environmental protection. This allows you to continue production in your facilities with peace of mind.

When air is compressed, heat is generated. The heat remains within the compressed volume, and the excess is removed before the compressed air is delivered to the pipeline. In many compressed air applications, there is a significant opportunity for energy savings. As the compressed air is cooled through the radiator and/or heat exchanger, a heat recovery system operating at 80–90% efficiency can increase the ambient air temperature by 15–25°C.

For example, when the compressor operates at full load, approximately 15 kW of energy recovery can be achieved per hour for 200 m³/h of intake air. This is a highly significant savings rate, helping you reduce overall operational costs.

The investment required to recover heat that would otherwise be discharged to the atmosphere can pay for itself in a short period. As seen, concerns about system costs are unnecessary. In some cases, heat recovery systems can fully meet the heating or hot water demand. As a result, costs decrease and when the recovered heat is fully utilized, the system can pay for itself in less than a year.

For example, consider an air-cooled compressor with 55 kW power and 159 l/s capacity. This compressor consumes 53.5 kW at full load. If it operates 48 hours per week and 52 weeks per year, the recoverable heat energy amounts to 133,000 kWh/year. At a unit cost of 0.07 Euro with electricity assumed as the energy source, this results in annual savings of approximately 9,300 Euros — a substantial financial benefit.

Beyond financial gains, the system also stands out for being environmentally friendly. Energy savings significantly reduce the amount of CO₂ emissions released into the atmosphere. For example, burning natural gas emits 0.21 kg(CO₂)/kWh. Based on the example above:

If 133,530 kWh/year of recovered heat is used for facility heating, the annual CO₂ emission reduction is:

133,530 × 0.21 = 28 tons of CO₂ per year, relieving the environment from a significant burden.

Additionally, in closed-circuit cooling systems, good water quality and stable temperature levels extend compressor service life—offering additional advantages. As seen, energy-saving systems offer considerable benefits to manufacturers.

Application Methods for Different Compressor Types

Oil-Injected Screw Compressor

-

The injected oil cools the air being compressed and ensures sealing for compressor components.

-

More than 75% of the heat generated during compression is absorbed by the oil coolers, while the rest is removed by the aftercooler or dissipated as heat loss.

Industrial Air Compressors

-

These systems typically feature an enclosed design. The hot air obtained through ducting is used for space heating.

-

Some units integrate an oil/water heat exchanger into the oil cooling system to generate hot water.

Water-Cooled Compressors

-

Besides the oil cooler and aftercooler, these systems are cooled via a water circuit. A heat exchanger can supply hot water for boiler feed or process needs.

Oil-Free Screw Compressors

-

Air-cooled systems usually consist of acoustically insulated enclosed packages. The heat obtained from the intermediate, final and oil coolers is distributed through hot air ducting.

-

In water-cooled systems, a heat exchanger supplies hot water for boiler feed or process requirements.

-

Certain models feature dual-pass coolers capable of generating hot water up to 90°C.

-

Some advanced models utilize waste heat for regeneration, integrated with chemical dryers.

How Do We Calculate Heat Recovery Potential?

Nearly all the energy supplied to a compressor is converted into heat. The more of this heat that is recovered and reused in other processes, the higher the overall system efficiency.

Recovered energy in kWh/year is calculated as:

W = [(K1 × Q1) + (K2 × Q2)] × TR

Where:

TR = Duration of recovered energy demand (hours/year)

K1 = Hours per year compressor runs under load

K2 = Hours per year compressor runs unloaded

Q1 = Available cooling water power under load (kW)

Q2 = Available cooling water power unloaded (kW)

Factors such as cooling system performance, distance to the consumption point, and heat demand duration affect the final result. When the heat flow is sufficiently high, selling recovered energy becomes an opportunity. The electricity provider may become your customer—allowing negotiations for investment, subcontracting, and delivery.

Managing energy recovered from multiple processes increases overall savings potential.

How Air-Cooled Systems Provide Energy Recovery

In compressed air systems, recovered energy may not always match the full heating requirement. The recovered amount varies depending on compressor load. To ensure optimal efficiency, there must be a consistent heat demand to match the recovered energy.

The best use of recovered heat is to support the energy already used by the system. This ensures that recovered heat is always utilized, enabling continuous savings.

Before compressed air is distributed through the pipeline, heat is released — resulting in waste heat. All compressed air systems require sufficiently safe cooling capacity. Cooling is achieved using ambient air, water networks, natural water sources, or process water in open or closed systems.

For example, a large industrial facility operating a compressor system that consumes 500 kW over 8,000 hours yearly uses approximately 4,000,000 kWh of energy. This is a substantial amount, and significant waste heat can be recovered as hot air or hot water. An oil-free screw compressor can produce water at 90°C, allowing this heat to be used within the facility—resulting in significant cost reductions and strong returns on investment.

Energy recovery systems are widely used in Scandinavian countries as a standard application. Many major suppliers recover heat using medium- and large-scale compressors with standard equipment — delivering environmentally friendly and low-cost solutions.

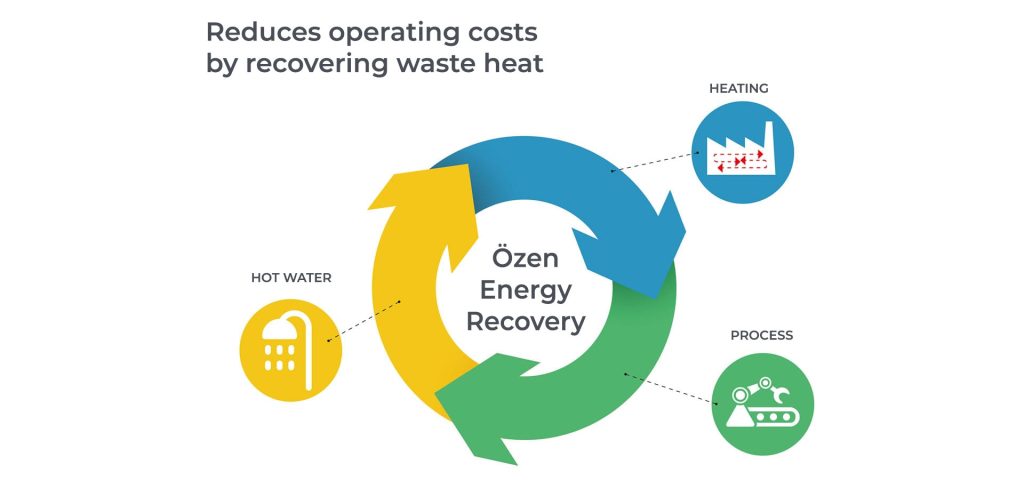

Özen Kompresör’s Energy Recovery Solutions

Özen Kompresör enables businesses to utilize the heat generated by their compressors through energy recovery technologies. The heat recovered using integrated heat exchangers can be used to heat production areas or warehouses.

These systems, which are simple to install, increase energy efficiency and reduce operational costs. With half a century of experience and a broad product range, Özen Kompresör provides safe, efficient, powerful, and durable compressed air solutions.

Özen Kompresör delivers the most accurate and effective energy-saving solutions for your facility and can install these systems in a short time. By increasing your energy efficiency, you can reduce operational costs with ease. Through Özen Kompresör, you can avoid unnecessary expenses and benefit from environmentally friendly solutions.