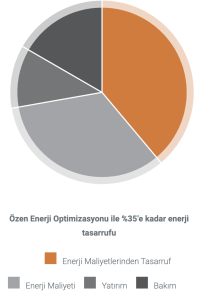

Sirius Series Ozen Energy Optimisation

Ozen Energy Optimisation

Energy Savings Even at Low Capacity Usage

Energy Savings Even at Low Capacity Usage

OSC V series screw compressors with frequency inverters adjust the motor speed according to the instant air demand of the business, preventing high energy consumption during low-capacity operations.

Constant Pressure Advantage

Since air demand is monitored in real time, air production is consistent, ensuring continuous stable pressure in the air line. This eliminates energy losses caused by load–unload cycles. Without making any changes to the compressor itself, different pressure requirements can be met simply by adjustments on the control panel.

Soft Start

Thanks to the frequency inverter controlling the motor speed, the initial start-up is much smoother and more comfortable compared to a standard compressor.

Frequency Inverter

Frequency Inverter

In manufacturing plants, air demand varies throughout the day depending on many factors. Standard compressors run in continuous load–unload mode to meet these changing air requirements. A screw compressor operating in unload mode consumes about 30–35% of its installed motor power without producing any air, resulting in unnecessary energy consumption. The frequency inverter in OSC V series compressors detects the instant air demand and adjusts the motor speed accordingly, delivering up to 35% energy savings and reducing operating costs.